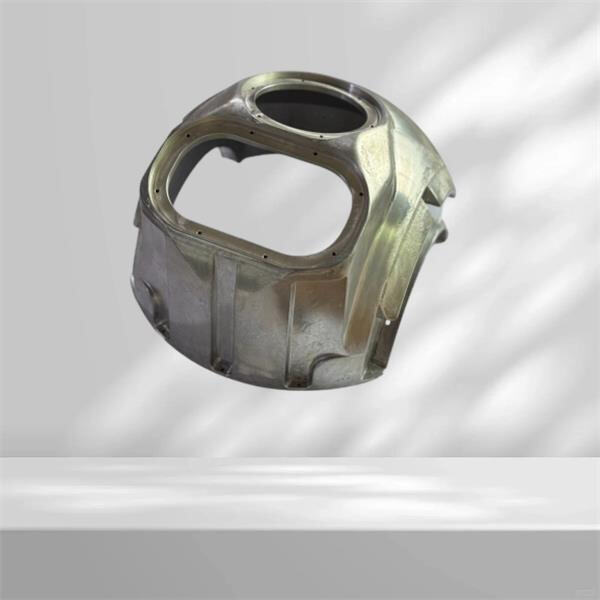

It’s referred to as gravity die casting, and that’s when the metal gets melted and poured into a mold.” The mold consists of two parts that fit together like a jigsaw puzzle. One part remains in a fixed position, the other part (in front) moves up and down to allow the metal to flow in.

The cool thing about Runpeng Precision Hardware gravity die casting is that it's capable of making super-accurate and intricate metal parts. This means that components such as car parts, airplane parts and even toys can be produced using Die Casting. And because the metal is poured into the mold with the aid of gravity, there are also no air bubbles or flaws in the final product.

Other ways to make metal parts also exist, such as sand casting or pressure die casting, but gravity casting is frequently chosen because it creates parts that are stronger and more precise. Sand casting can be messy and less accurate, and pressure die casting requires costly machinery and may be more difficult to control.

This Runpeng Precision Hardware casting method is applied in a variety of industries, including that of automotive, aerospace and electronics. In the automotive sector, gravity die casting is the process that is used to form engine blocks, wheels, and even whole vehicle bodies. In the aerospace sector, Investment Casting creates wings, landing gear and other critical parts of airplanes. The electronics industry also uses gravity die casting to produce products like computer parts and smartphone components.

To get the most out of Runpeng Precision Hardware gravity die casting, you need to keep the mold clean. You should also pour your metal into your mold at the correct temperature and pressure. Finally you want to use only the highest quality metal and avoid any impurities for optimal results.