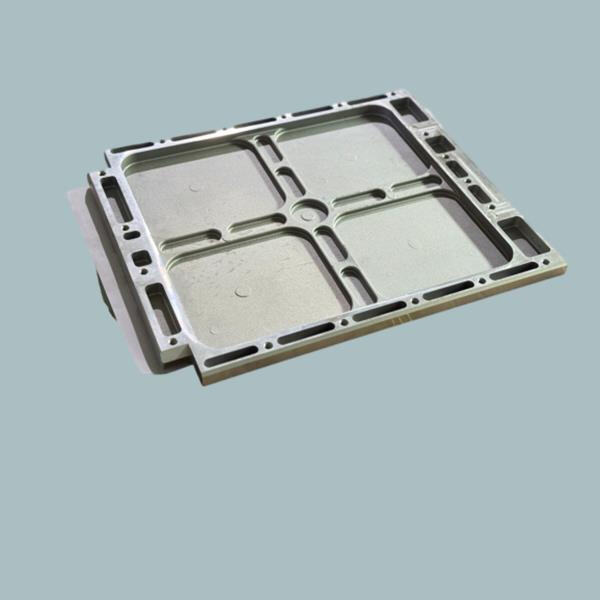

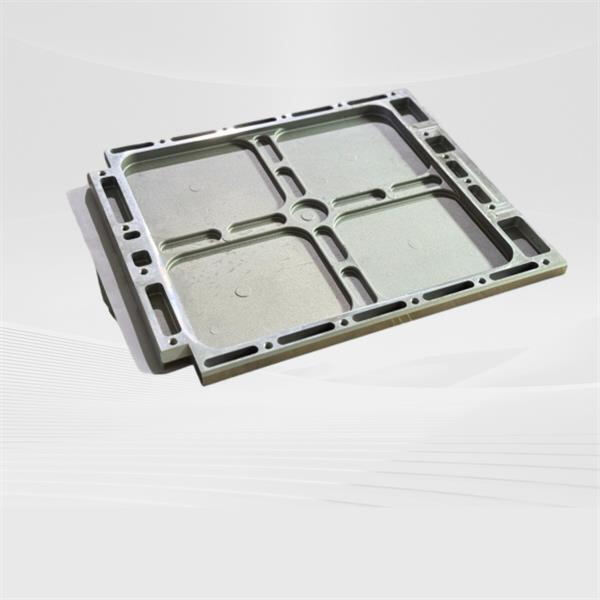

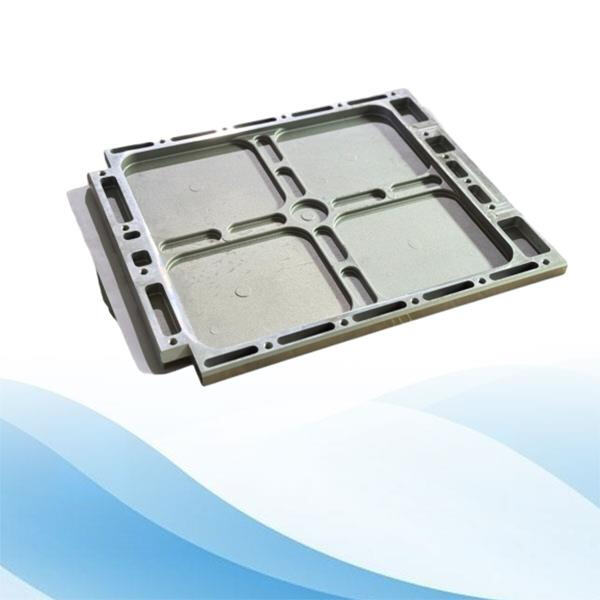

We here at Runpeng Precision Hardware utilize this method to develop quality products for a range of industries. So – what on earth is gravity casting aluminum, and why is this type of casting method so widely used in the world of manufacturing? Aluminium gravity casting is a casting process where the flowing molten aluminium is poured into a tool via gravity. This process will enable us to cast objects with more intricate shapes and designs that might otherwise be impossible to create with casting. Gravity casting One of the benefits of gravity casting is that it permits the creation of highly detailed products. This implies that components manufactured in this way are typically of a superior quality and more uniform in dimensions and surface finish.

Another benefit of gravity cast aluminum is that it is the most inexpensive route of producing the ideal wheels. The method is quite convenient and does not dependent on cumbersome instruments or apparatus. It’s the reason why this is such a common choice for companies which desire to make tremendous volumes for components for cheap. What’s more, it is also suitable for producing products of different sizes, small parts as well as big products, thus, is quite multifunctional in the field of the manufacture.

A major advantage of gravity cast aluminum is its accuracy and precision. The liquid aluminium is cast in a controlled rate, thus fine details and small features can be reproduced very accurately. This precision is a requirement for certain industries, e. g., the aerospace and automotive industries, which need fine tolerances to work effectively. Our gravity cast process enables us to produce products of superior precision and finish quality utilizing cutting edge technology and processes.

Power—Casting Gravity Machining serves multiple industries, from automotive and aerospace to electronics and consumer products. This process is especially useful for fabricating parts and articles where high strength, durability, and precision are desired. Gravity cast aluminium is used in a variety of applications from the automotive, aerospace, to the military. The flexibility of this method of casting ensures it's the perfect solution for any business that wants to produce durable products that are also lightweight.

Here At Runpeng Precision Hardware, we are constantly investing in the latest gravity casting aluminium technologies to improve both the quality and the performance of all our aluminium casting. Utilizing the most advanced technology with experienced and talented craftsmen, we are able to manufacture parts that meet outstanding quality. We have a team of professionals that partner closely with our clients to create custom solutions that meet their specific needs. “We are committed in providing a smart and reliable solutions to. Add value to you product. Reduce the weight of your products Reduce the number of components of your products• Save time in operations process (assembling, finishing, packing) Improve life cycle of your productWhether it is optimizing a part design, including a surface finish in a component, we want to give you results that surprise you.