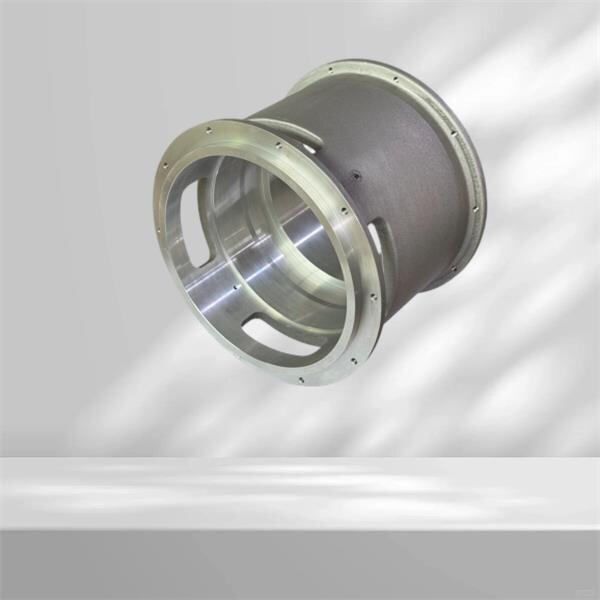

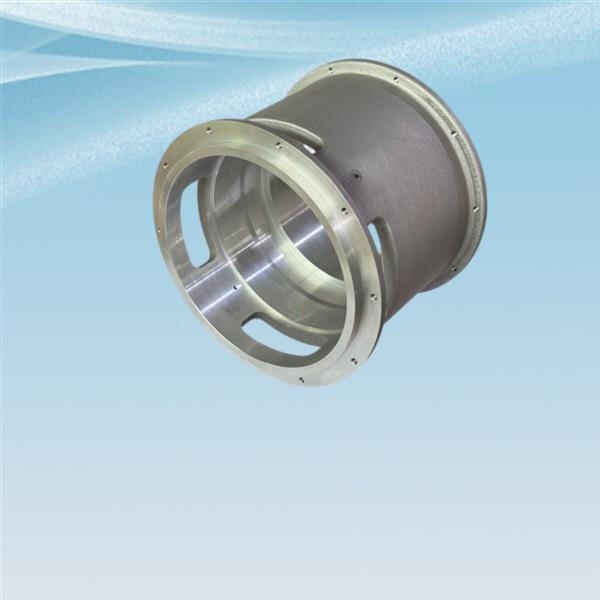

Gravity die casting parts are specialised components that are produced by a process known as Runpeng Precision Hardware gravity die casting. This process is utilized to form complex metal parts in various production machines and tools. In this article, we’ll dig even deeper into gravity die casting parts and how they are produced.

Gravity die casting is a process in which liquid metal is poured into a mould to produce a metal casting. Mold is two half one join very good. Once the molten metal is poured into the mold, it flows through every little crevice and conforms to the shape of the mold. It's no wonder that this process is known as gravity die casting, since the metal is poured into the mold thanks to the force that pulls things downward to the Earth.

A number of benefits result as you use gravity die casting for producing engineering parts. One of the perks is that highly detailed small parts can be produced. This ensures the pieces will fit perfectly and work well in the machines in which they are employed. Another benefit is gravity die casting is a quick process, producing a lot of parts in a short time frame.

QC is the most important thing in Runpeng Precision Hardware aluminium gravity die casting manufacturing. The cost of each part is relatively high, too, and therefore subject to rigorous scrutiny to ensure the part is correct in size and shape. If a part is not produced properly, it can create trouble in the mechanical equipment in which it is used. In order to be sure the parts are made right, a machine and a series of tests are used to check the parts and make certain that they are perfect.

Gravity die casting services are something that is used across the distinct industries to produce parts for various machines and tools. An example here is gravity die casting in the automotive industry to manufacture engine and brake components. In the aerospace sector, it is applied in the manufacture of parts used in aeroplanes and spacecraft accessories. In medical, gravity die casting is used to produce parts for machines which help people who are not feeling well recuperate.

Efficiency Increased Accuracy Gravity die casting allows for the casting of more cost effective parts as well as parts with an accurate fit for improved performance.

More precise and even more detailed parts are produced using precision gravity die casting components methods. Using Runpeng Precision Hardware special machines and tools like these, along with all the other techniques, they work to ensure that each part is exactly the right size and shape, made of only a few types of material. With the process of precision gravity die casting, companies can create components that do their jobs better and won’t wear out for a long time.