- Overview

- Recommended Products

Runpeng Precision Hardware

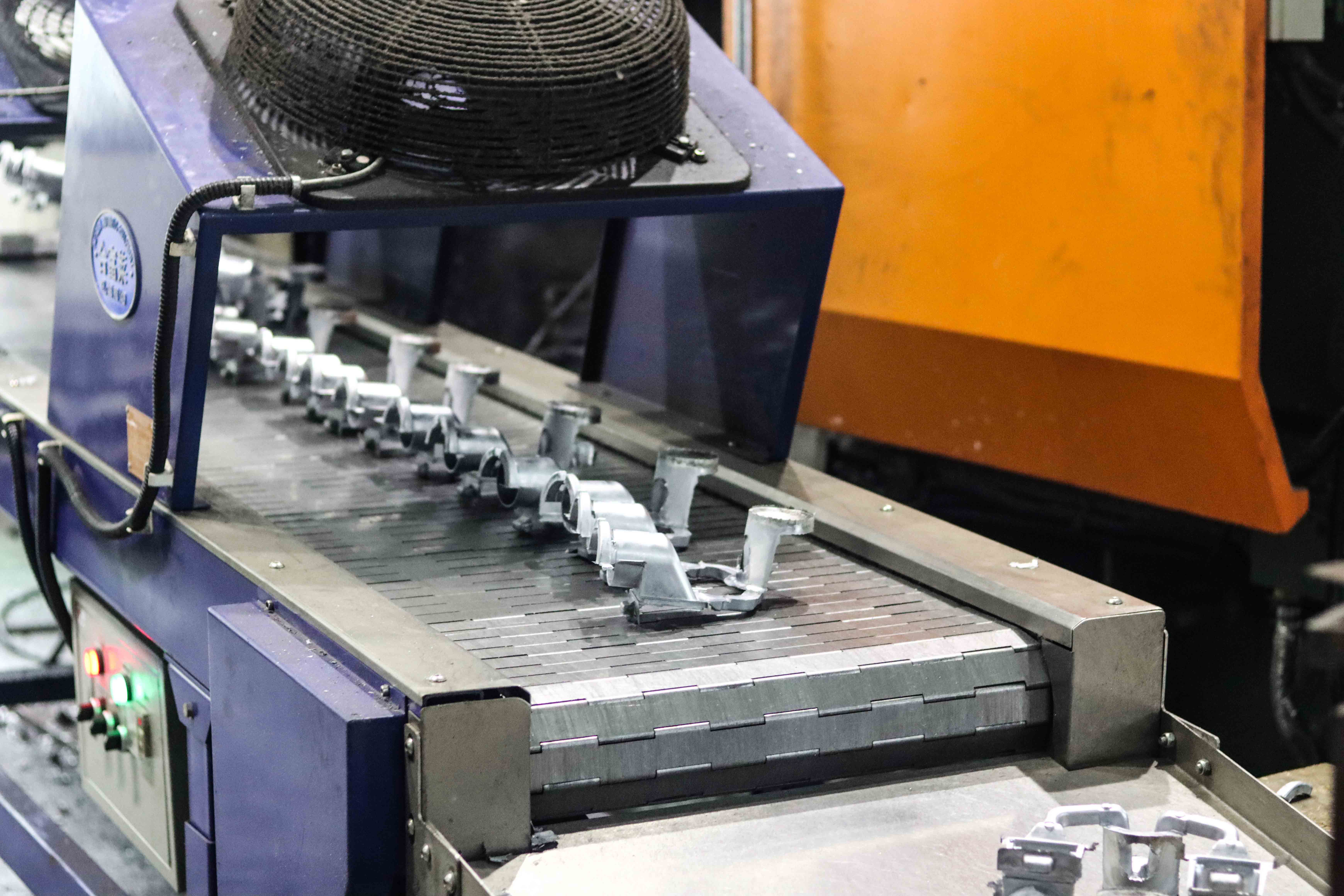

Runpeng Precision Hardware offers top-of-the-line Custom Zamak Die Casting Parts and Zinc Alloy Die Casting Parts for all of your manufacturing needs. Our high-quality die casting parts are perfect for a wide range of applications, from automotive to electronics to aerospace and beyond.

Custom Zamak Die Casting Parts are made from a durable zinc-aluminum alloy that is known for its strength and corrosion resistance. This makes them ideal for use Runpeng Precision Hardware in demanding environments where reliability is key. Our die casting parts are precision-engineered to meet your exact specifications, ensuring a perfect fit every time. Whether you need a complex component or a simple part, we can deliver a solution that meets your needs.

Our Zinc Alloy Die Casting Parts are crafted from a premium blend of zinc and other metals, making them highly durable and long-lasting. These parts are lightweight and easy to work with, making them perfect for applications where weight is a concern. Whether you need a small batch of parts or a large production run, we can handle your order with speed and efficiency.

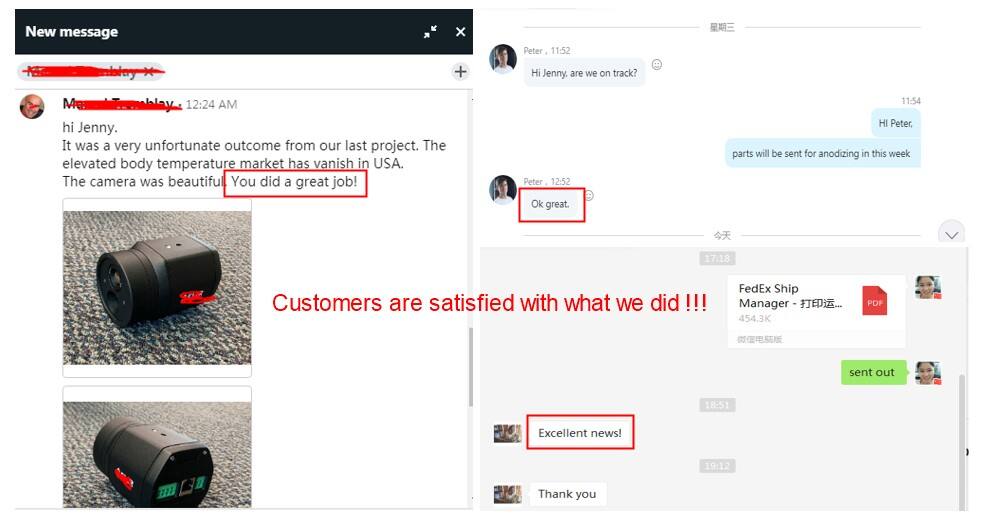

At Runpeng Precision Hardware, we take pride in our commitment to quality and customer satisfaction. Our experienced team of engineers and technicians work tirelessly to ensure that every die casting part we produce meets the highest standards of excellence. We use the latest technology and techniques to deliver parts that are consistent in quality and performance.

When you choose Runpeng Precision Hardware for your die casting needs, you can trust that you are getting the best in the industry. Our Custom Zamak Die Casting Parts and Zinc Alloy Die Casting Parts are competitively priced and backed by a team of experts who are dedicated to your success. Whether you need a custom solution or a standard part, we have the expertise and resources to deliver a product that exceeds your expectations.

Don't settle for subpar parts – choose Runpeng Precision Hardware for all of your die casting needs. Contact us today to learn more about our Custom Zamak Die Casting Parts and Zinc Alloy Die Casting Parts, and discover why we are the preferred choice for manufacturers around the world.

Mold Material |

SKD61, H13 |

Cavity |

Single or multiple |

Mold Life Time |

50K times |

Product Material |

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

Surface Treatment |

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

step, dwg, igs, pdf |

Certificates |

ISO 9001: 2015 & IATF 16949 |

Payment Term |

T/T, L/C, Trade Assurance |

800T die-casting machine |

1 |

630T die-casting machine |

1 |

400T die-casting machine |

2 |

300T die-casting machine |

1 |

280T die-casting machine |

2 |

180T die-casting machine |

1 |

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years' export experience.

5. Small order also is welcomed.

6. We provide one-stop service, including mold and assembly.

7. All your information is confidential, and we can sign NDA as well

One-stop Solution

Quality Guarantee

Customer Service

Our Regular Customer

Our Regular Customer

Our Regular Customer

Our Regular Customer

Our Regular Customer

Q1. Are you a factory or trade company? We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China.

Welcome to visit our factory.

Q2. What kind of production service do you provide?

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment.

Q3. How about the lead time?

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got ISO9001: 2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q5. How long should we take for a quotation? After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

Q6. What is your quotation element?

Drawings or Sample, Material, Finish, and Quantity.

Q7. What is your payment term?

Mold: 50% prepaid, balance after sample approval. Goods: 50% prepaid, balance T/T before shipment.