More specifically, precision metal stamping is a form of art. You know those cool metal parts you see in machines or appliances that fit so perfectly together like a puzzle? Very well, these are the perform of precision metal stamping. The method refers to a metalworking process which is closely connected with precision and delicate parts that fits together perfect

Then the big machine corresponding a heavy metal plate inside it. That this machine has pressurized lids that thick plastic sheets come down on top of the metal plate in just the right amount of pressure to enable it to take on a perfect form. The process is called precision metal stamping. In a sense, it is like one huge metal cookie cutter but rather than cutting cookie dough, it cuts exact shaped hefty metal components which are crucial in many of the devices we make use of on a day-to-day basis.

Did you ever realize just how perfectly a jigsaw puzzle goes together? That is what a precision metal stamping it! These are very carefully designed and stamped with clearances of 1/1000th inch. Together, these components are put together to form complex parts that allow machinery to plastic extrusion keep running easily and function well. From small screws to large gears, precision metal stamping ensures that each and every piece is manufactured properly with the utmost care.

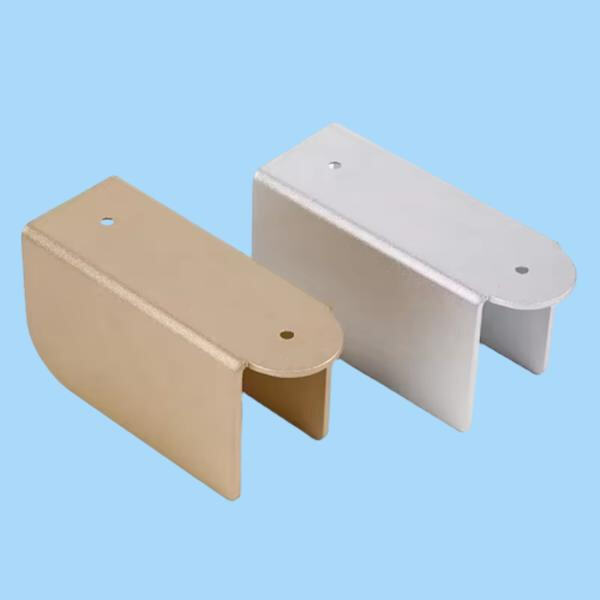

When it comes to precision metal stamping, that is not just smacking a hammer into steel. A mix of art and science, really, once you get to understand how the metal works when stressed. Since then, engineers and technicians use sophisticated tools and techniques in order to stainless steel door hinges form metal components as per rigid requirements. With exact measurements and calculations, each part is made to the most accurate specifications.

Producing metal parts by traditional means was also quite time consuming and labor intensive. However, there has been a revolution in the manufacturing field with precision metal stamping. At present, companies such as Runpeng Precision Hardware are able to metal gate hinges manufacture large batches of metal parts quickly, accurately and efficiently. That means products can be produced quicker and for less, which creates a cost saving that consumers see. Precision metal stamping has really revolutionized the game of manufacturing.

Metal parts should be of quality-grade. Runpeng Precision Hardware also employs precision metal stamping, which allows companies to build components that are as accurate in the respect of their dimensions and properties, as they are durable and long-lasting. Utilizing cutting-edge techniques and advanced machinery, they injection molding are able to manufacture metal parts that conform to strict quality standards. It also ensures that they work as intended, and here we see the value of money every time a consumer buys these products.