Runpeng Precision Hardware

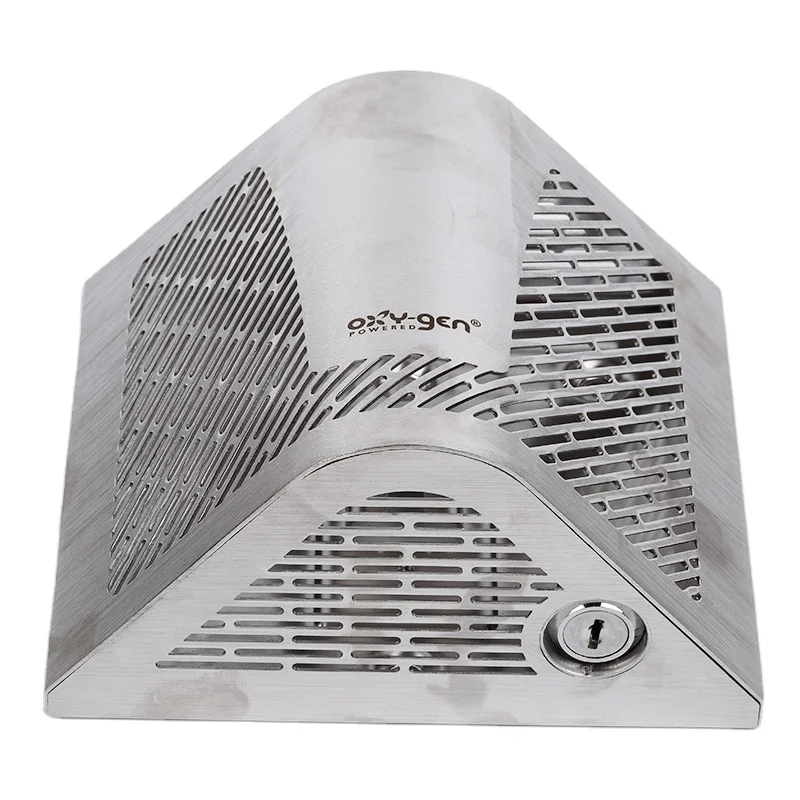

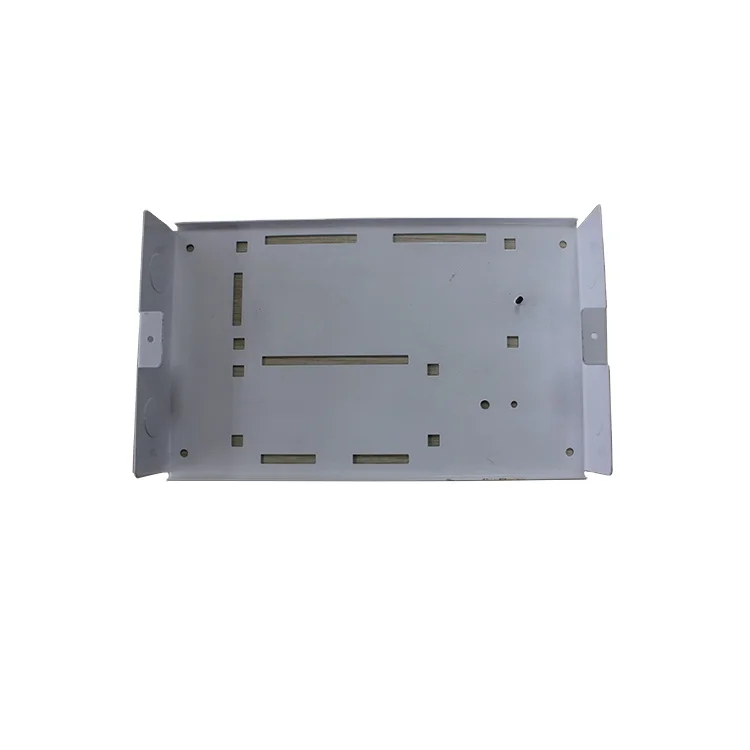

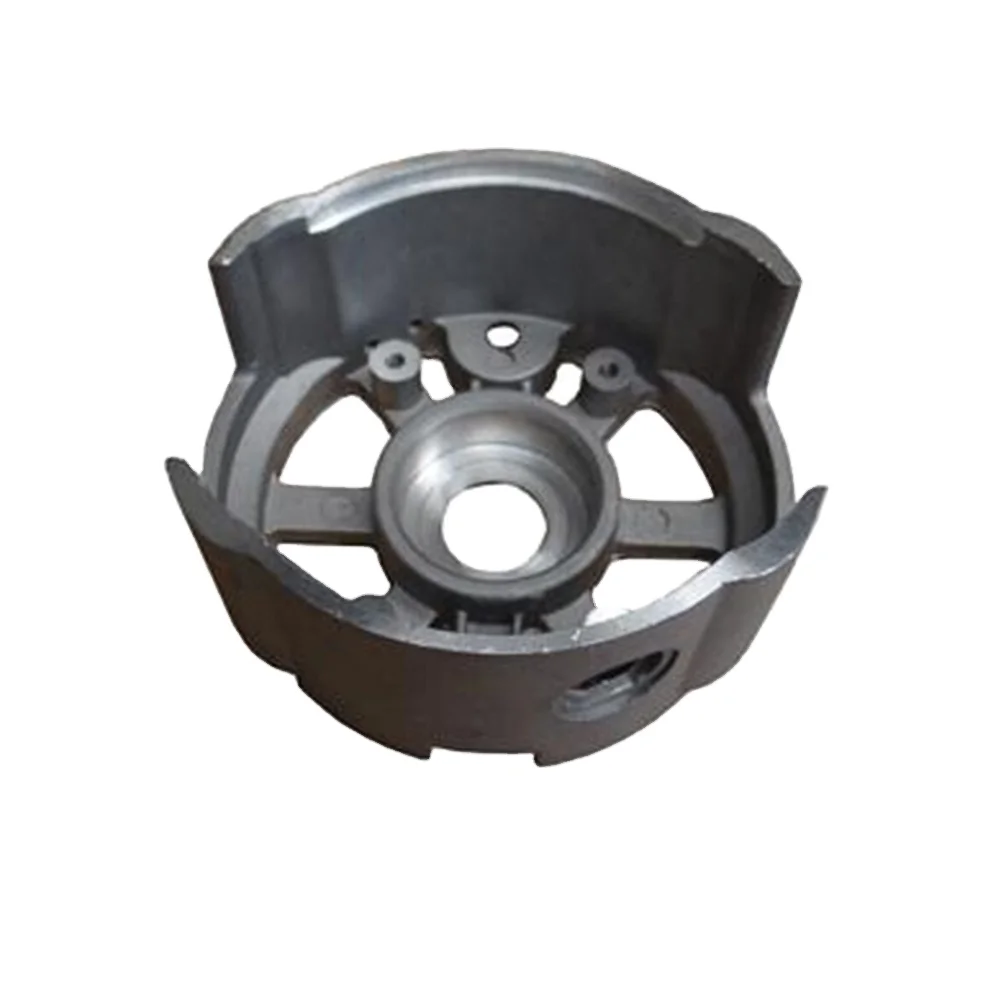

Introducing Runpeng Precision Hardware's Custom Sheet Metal Work Stamping Parts Stainless Steel Products Sheet Metal Fabrication.

Our products are crafted with precision and expertise, offering high-quality sheet metal work that is sure to meet the demands of your project. Whether you are in need of custom stamped parts or stainless steel products, Runpeng Precision Hardware has you covered.

Our sheet metal fabrication process ensures that each product is crafted with care and attention to detail. We use top-of-the-line materials to ensure durability and longevity, making Runpeng Precision Hardware our products a reliable choice for your needs. Our stainless steel products are designed to resist rust and corrosion, making them ideal for a wide range of applications.

With Runpeng Precision Hardware, you can trust that your custom sheet metal work will be completed to your exact specifications. Our team of experts is committed to providing you with the highest quality products that meet your unique needs. From prototype development to full-scale production, we have the capabilities to handle any project, big or small.

Whether you are in the automotive, aerospace, or electronics industry, our custom sheet metal work is suitable for a variety of applications. Our products are designed to withstand the rigors of daily use, making them a reliable choice for your business.

At Runpeng Precision Hardware, we take pride in our ability to deliver top-notch sheet metal fabrication services. Our commitment to quality and customer satisfaction sets us apart from the competition. We strive to exceed your expectations and deliver products that meet your needs and exceed your expectations.

So why settle for anything less than the best? Choose Runpeng Precision Hardware for all your custom sheet metal work stamping parts stainless steel products sheet metal fabrication needs. Experience the difference that quality and expertise can make in your projects. Place your order today and see why Runpeng Precision Hardware is the leading choice for sheet metal fabrication.

|

Cr12 |

|

300K times |

|

1) AL1060, AL6061, AL6061, AL5052

2) Steel, mild steel, SPCC3) SS201, SS303, SS304, SS316, SS316L

4) SPTE, galvanized sheet

5) Brass, copper

|

|

Anodized, powder coating, lacquer coating, black oxide |

|

1) According to customers' drawings

2) According to customers' samples |

|

step, dwg, igs, pdf |

|

ISO 9001: 2015 & IATF 16949 |

|

T/T, L/C, Trade Assurance |

|

|

|

|

|

|

|

|

Hydraulic shearing machine |

|

|

|

European and American market

We now have 200 customers from all over the world.

1. We have own factory and 80% of staff in our company worked for more than 10 years.

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years' export experience.

5. Small order also is welcomed.

6. We can also provide one-stop service, including mold and assembly.

7. All your information is confidential, and we can sign NDA as well.

One-stop Solution

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping

Quality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system

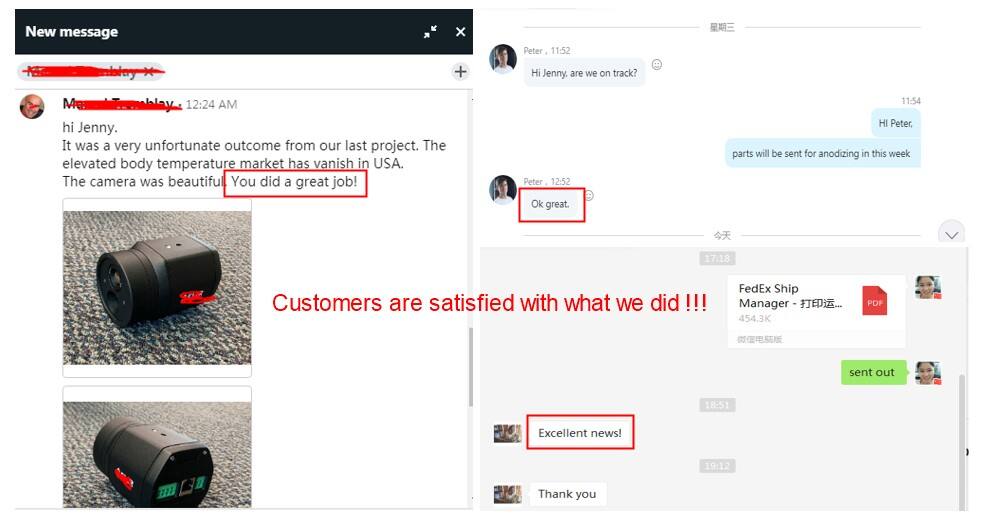

Customer Service

Every client is served by a specialized sales for timely technical support and after-sales service

Our Key Customer

We have cooperated since 2007. Annual order more than $1.2 million.

Our Regular Customer

We have cooperated since 2007. Annual order more than $1 million.

Our Regular Customer

We have cooperated since 2007. Annual order more than $0.7 million.

Our Regular Customer

We have cooperated since 2016. Annual order more than $0.8 million.

Our Regular Customer

We have cooperated since 2016. Annual order more than $0.7 million.

Q1. Are you a factory or trade company?

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China

Welcome to visit our factory.

Q2. What kind of production service do you provide?

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment.

Q3. How about the lead time?

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got ISO9001: 2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

Q6. What is your quotation element?

Drawings or Sample, Material, Finish, and Quantity.

Q7. What is your payment term?

Mold: 50% prepaid, balance after sample approval.

Goods: 50% prepaid, balance T/T before shipment