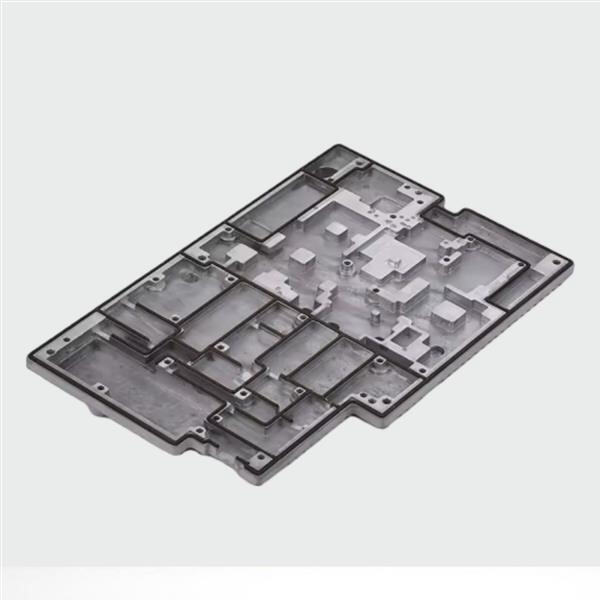

Mould die casting is a groovy way to mould metal into anything we want, such as bits for cars or tools. We employ this approach to produce high-quality metal parts at Runpeng Precision Hardware. You do this by melting metal until it’s ridiculously hot and then liquid, then pouring it into a mold in the shape of the part you want. When it cools off, you’ve got a metal part.

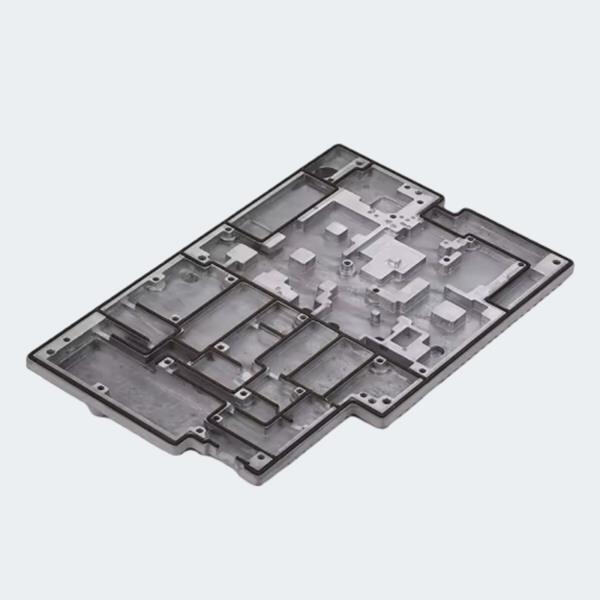

At Runpeng Precision Hardware, we understand the significance of how much making stuff cost. That’s why, when it comes to our mould die casting, we focus on providing the best work for the best price. We double and triple check to make sure everything’s just right, so we don’t waste materials — or time. That allows us to keep costs down for the people who purchase our parts, making it a little easier and a little less risky for them to go out and make their products without spending a ton of money.

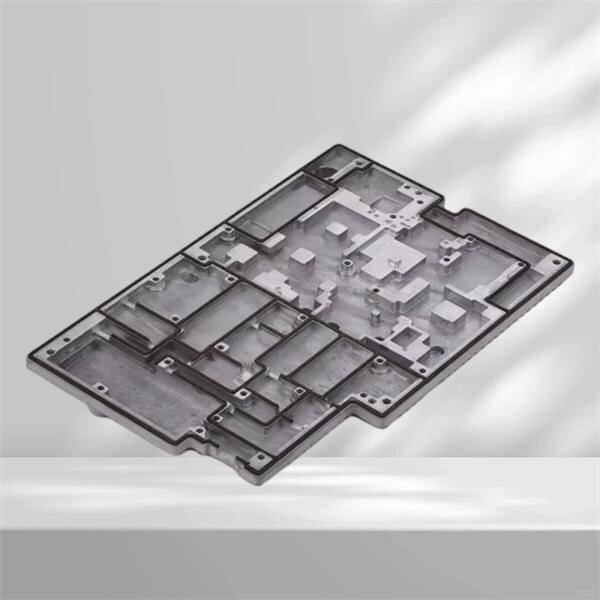

Runpeng Precision Hardware, our team is really talented in ensuring that all metal parts are perfect without burrs and clean. The machines are very precise, so every part looks the way it is supposed to. This is awesome for me, since when somebody uses them to build something together later, it means that all of the parts should fit just right together. Our process is also rapid, so we can make lots of parts swiftly without making a mess of things.

We understand that everyone is looking for something a bit different. Here at Runpeng Precision Hardware Co., Ltd, we can customize our mould die mould casting process to meet your requirements perfectly. If you need a certain metal or a specific shape, we can handle it. We love finding the best way to make the parts that customers dream up.

My team stays at the forefront of every technology ensuring we do the best job. We also got a lot of smart people who know a shit ton about mould casting. That’s why we can make parts that are truly reliable and strong. We are always learning new things and finding ways to the work even better.