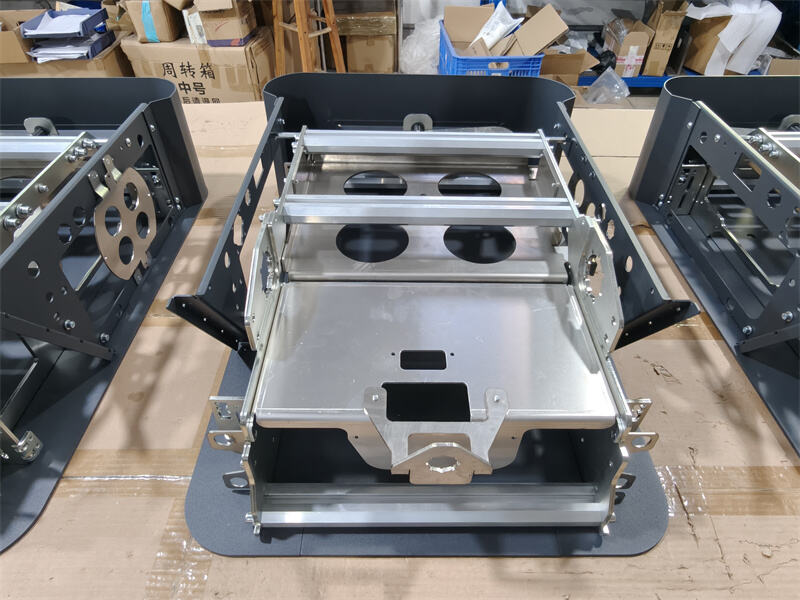

With 31 years of accumulated experience in metal customization, Shenzhen Runpeng Precision Hardware Co., Ltd. has effectively assisted Germany's Carrybots in developing core components for high-precision logistics AGVs (Automated Guided Vehicles). As a professional OEM metal customization service provider with 31 years of dedication to the field, our company recently successfully delivered the core metal structural components for Carrybots' logistics AGVs — these parts are applied in the HERBIE series of autonomous transport vehicles under Carrybots. Leveraging sheet metal processing and powder coating as the core technologies, the components perfectly meet the rigorous standards of "±3mm positioning accuracy and >99% availability". Behind this achievement lies the technical capability honed through our 31 years of experience in sheet metal customization.

Since its establishment in 1994, our company has consistently focused on the precision metal customization sector, particularly accumulating profound expertise in die casting technology: from mold development to high-pressure die casting, we can customize complex metal parts ranging from a few grams to dozens of kilograms with a precision control of ±0.05mm. We have served international clients across dozens of industries, including automotive, electronics, and high-end equipment. This collaboration with Carrybots is rooted in the client's demand for "high precision + high stability" — our engineering team not only completed laser cutting, bending, and welding of the components using sheet metal technology, locking the dimensional error within ±0.5mm, but also optimized the reinforcing ribs at the stress points based on 31 years of sheet metal structural design experience. This optimization increased the load-bearing capacity by 20%, fully adapting to the high-frequency transportation scenarios of the HERBIE series in production workshops and logistics warehouses.

For the surface treatment, we adopted a black matte powder coating process, which withstood a 480-hour salt spray test without corrosion. This not only meets the wear-resistant and stain-resistant requirements of industrial environments but also highly aligns with the minimalist industrial design style of Carrybots' products. From client demand docking and drawing detail optimization to sample prototyping confirmation and mass production delivery, our team completed the order in just 15 days. This efficiency is supported by our comprehensive process production lines covering die casting, stamping, injection molding, and CNC machining, as well as the standardized process system accumulated over 31 years of serving international clients.

Currently, these components have been successfully integrated into the HERBIE series logistics AGVs, serving the production and logistics links of internationally renowned enterprises such as MAN and TATA, and helping them achieve the Industry 4.0 upgrade of "unmanned transportation + cost reduction and efficiency improvement".

"Thirty-one years of technical accumulation enable us to not only accurately match clients' process requirements but also quickly respond to the delivery rhythm of the global market." Whether you need customization of a single process such as die casting, sheet metal processing, or CNC machining, or an integrated multi-process solution like the one for Carrybots, you can submit your needs through the "Custom Consultation" channel on our website. We will arrange a dedicated salesperson and engineer to connect with you within 24 hours, providing one-stop customization services from scheme design and sample prototyping to mass production. We aim to help your products quickly enter the market with higher precision and better quality.