- Overview

- Recommended Products

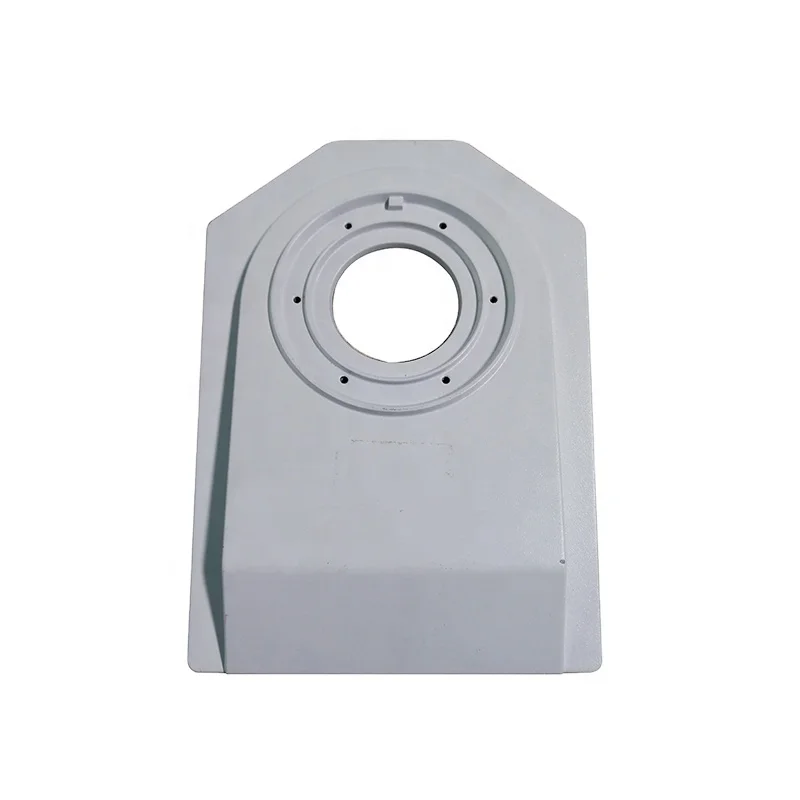

Introducing the Runpeng Precision Hardware Custom Stainless Steel Lost Wax Casting OEM Investment Castings. This top-quality product is perfect for a wide range of applications, from industrial machinery to automotive components

Crafted using the lost wax casting method, these investment castings are durable and precise. Made from high-quality stainless steel, they are built to last and can withstand even the toughest conditions. The OEM design allows for complete customization, ensuring that each casting meets your exact specifications and requirements

Whether you need a single prototype or a large production run, the Runpeng Precision Hardware Custom Stainless Steel Lost Wax Casting OEM Investment Castings are the perfect solution. Our team of experienced craftsmen will work closely with you to ensure that your project is completed to the highest standards, on time and on budget

With the Runpeng Precision Hardware brand, you can trust that you are getting a reliable and high-quality product. Our investment castings are built to withstand the test of time, making them a cost-effective and efficient choice for your business

The versatility of these castings makes them ideal for a wide range of industries. From aerospace to automotive, construction to energy, the Runpeng Precision Hardware Custom Stainless Steel Lost Wax Casting OEM Investment Castings can be used in countless applications

Invest in the Runpeng Precision Hardware Custom Stainless Steel Lost Wax Casting OEM Investment Castings today and experience the difference that quality and precision can make in your projects. With our commitment to excellence and customer satisfaction, you can trust that you are getting the best product on the market

Don't settle for subpar investment castings. Choose the Runpeng Precision Hardware brand and get the quality and durability that your projects deserve. Invest in the best – choose the Runpeng Precision Hardware Custom Stainless Steel Lost Wax Casting OEM Investment Castings

Product Material |

Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, Copper |

Process |

Lost wax casting + CNC machining |

Surface Treatment |

Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast |

Heat Treatment |

Annealing, Normalizing, Hardening, Tempering |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

Step, Dwg, Igs, Pdf |

Certificate |

IATF 16949, ISO 9001:2015 |

Payment Term |

T/T, L/C, Trade Assurance |

One-stop Solution

Quality Guarantee

Customer Service

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China

Q2. What kind of production service do you provide4

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information your 2D/3D drawings or samples, we will quote you within 2 days

Q6. What is your quotation element

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment