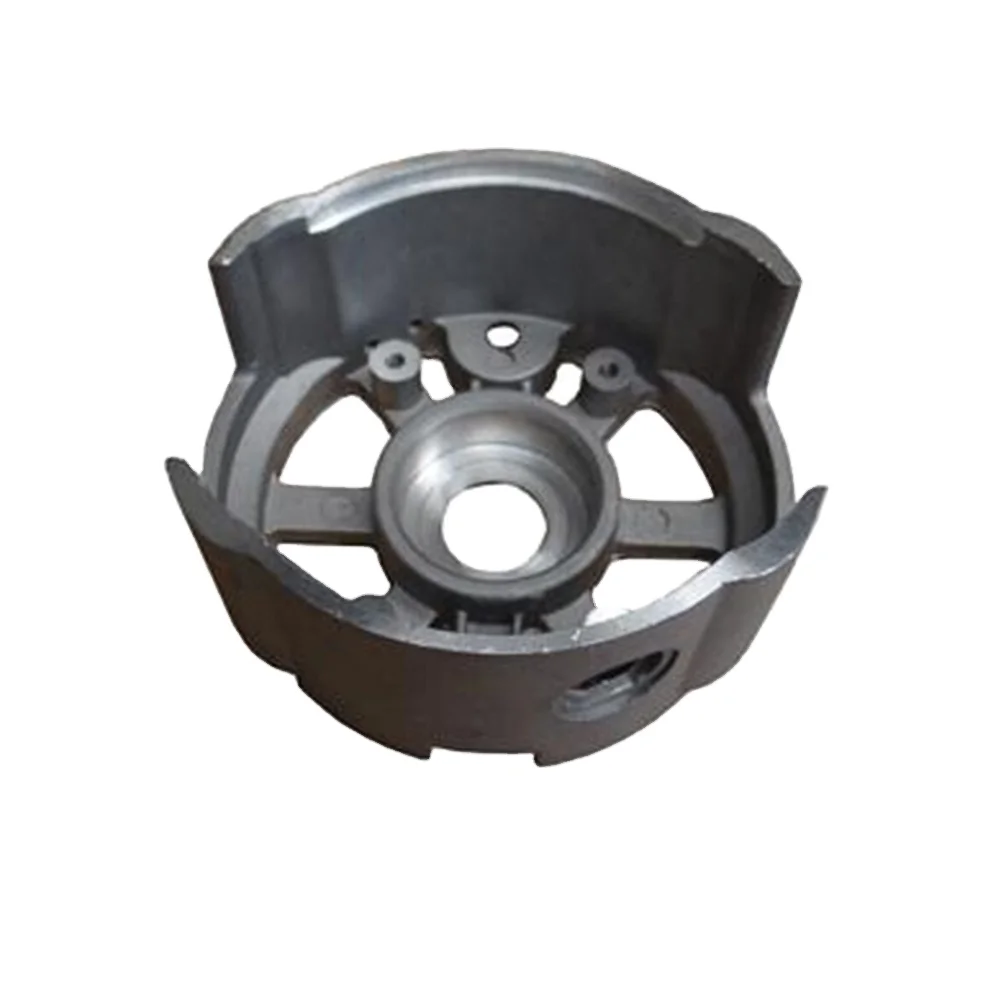

Looking for a durable and high-quality enclosure for your electronic devices? Look no further than the Custom Aluminum Enclosure from Runpeng Precision Hardware. This sleek and modern enclosure is perfect for protecting your electronics while providing a sleek and professional look.

Made from high-grade aluminum, this enclosure is designed to withstand daily wear and tear. The aluminum material is also lightweight, making it easy to transport and install. The enclosure is also resistant to corrosion and rust, ensuring that your electronics are safe and secure.

In addition to its durability, the Custom Aluminum Enclosure also offers excellent customization options. Create a unique look for your enclosure with custom finishes and colors, ensuring that it matches your branding and aesthetic. You can also add custom cutouts and features to accommodate your specific electronic devices.

Not only does the Custom Aluminum Enclosure provide top-notch protection, but it also offers superior functionality. The enclosure is designed for easy access to your electronic devices, with convenient openings and access points for cables and connectors. The enclosure also features ventilation holes to prevent overheating and maintain optimal performance for your electronics.

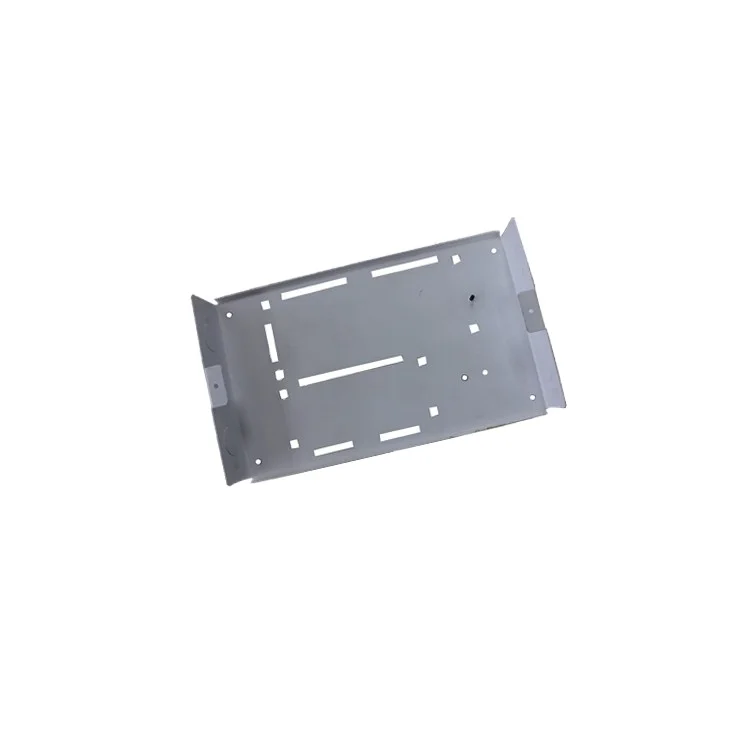

Looking for an enclosure that offers both durability and customization? Consider the Aluminum Metal Stamping and Welding Enclosure from Runpeng Precision Hardware. This enclosure is crafted with precision metal stamping and welding techniques for exceptional strength and stability.

The Aluminum Metal Stamping and Welding Enclosure is perfect for industrial applications, providing a rugged and reliable housing for your electronic components. The enclosure is made from high-quality aluminum, ensuring long-lasting performance and protection for your valuable equipment.

With its metal stamping and welding construction, this enclosure offers superior durability and resistance to impact and vibration. The enclosure is also resistant to high temperatures, making it ideal for harsh environments. The secure welding ensures that your electronic components are safe and secure.

Like the Custom Aluminum Enclosure, the Aluminum Metal Stamping and Welding Enclosure can be fully customized to meet your specific needs. Choose from a variety of finishes and colors to match your branding, and add custom features and cutouts to accommodate your electronic devices

|

Cr12 |

|

300K times |

|

1) AL1060, AL6061, AL6061, AL5052

2) Steel, mild steel, SPCC3) SS201, SS303, SS304, SS316, SS316L

4) SPTE, galvanized sheet

5) Brass, copper

|

|

Anodized, powder coating, lacquer coating, black oxide |

|

1) According to customers' drawings

2) According to customers' samples |

|

step, Dwg, Igs, pdf |

|

ISO 9001:2015 & IATF 16949 |

|

T/T, L/C, Trade Assurance |

|

|

|

|

|

|

|

|

Hydraulic shearing machine |

|

|

|

Europe and America market

We now have 200 customers from all over the world.1. We have own factory and 80% of staff in our company worked for more than 10 years.

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years' export experience.

5. Small order also is welcomed.

6. We can also provide one-stop service, including mold and assembly.

7. All your information is confidential, and we can sign NDA as well

One-stop Solution

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping

Quality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system

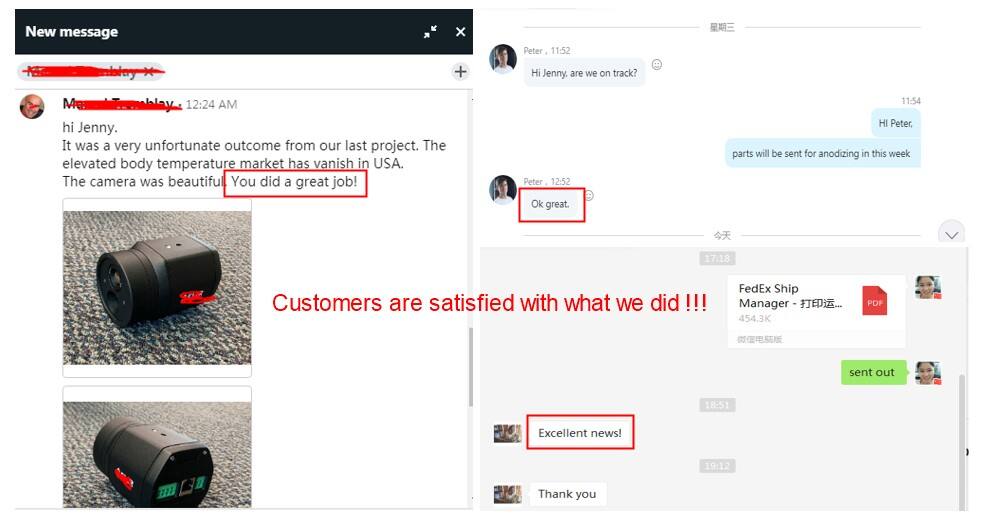

Customer Service

Every client is served by a specialized sales for timely technical support and after-sales service

Our Regular Customer

We have cooperated since 2007

Annual order more than $1.2 million

Our Regular Customer

We have cooperated since 2007Annual order more than $1 million

Our Regular Customer

We have cooperated since 2007Annual order more than $0.7 million

Our Regular Customer

We have cooperated since 2016Annual order more than $0.8 million

Our Regular Customer

We have cooperated since 2016Annual order more than $0.7 million

Q1. Are you a factory or trade company

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China. Welcome to visit our factory

Q2. What kind of production service do you provide

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 2 days

Q6. What is your quotation element

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment.