Customized Die-Casting Service High-Precision Metal Sand Mold Casting Carbon Steel Zinc Alloy Aluminum Radiator

- Overview

- Recommended Products

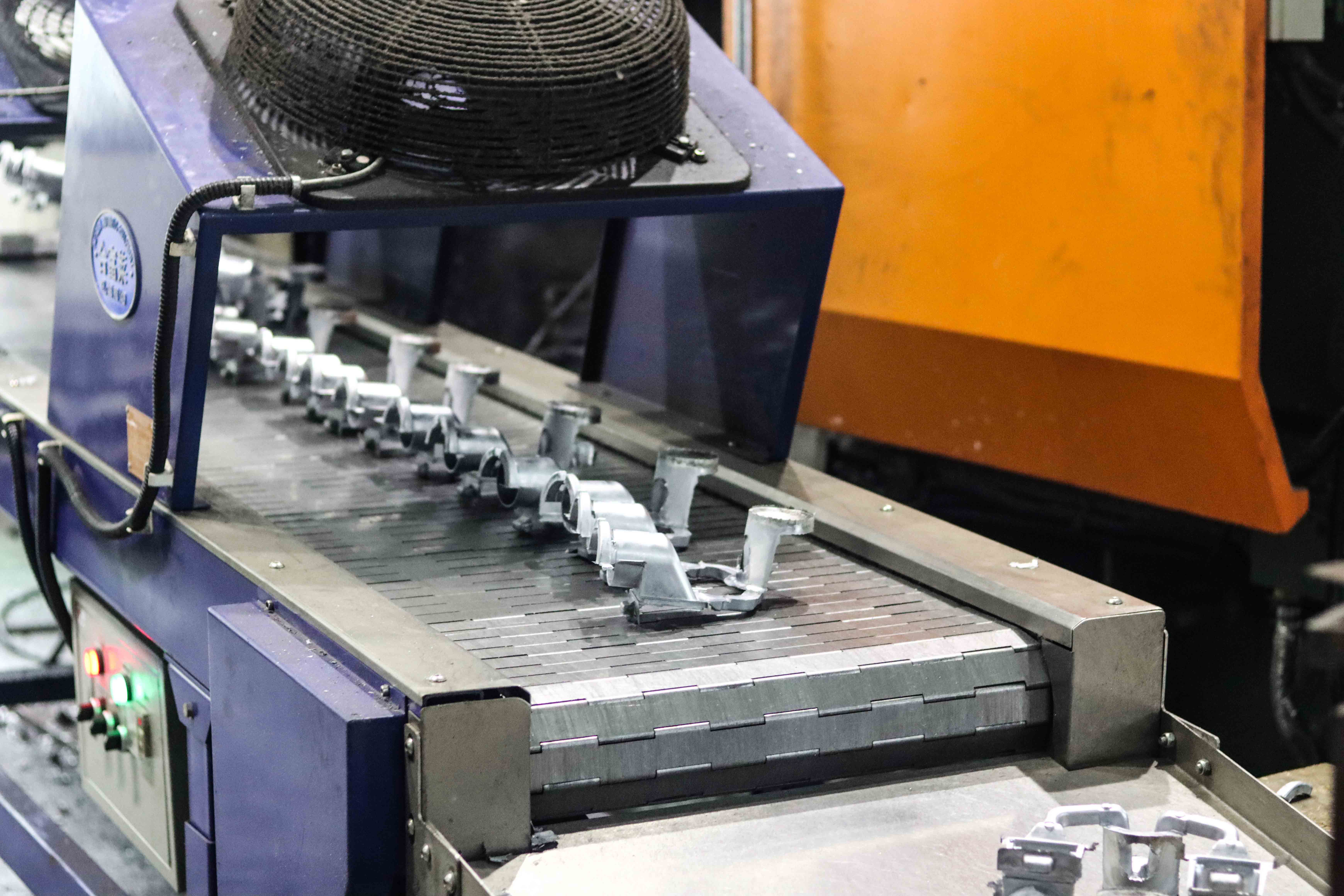

Introducing, the Customized Die-Casting Service by Runpeng Precision Hardware – your trusted partner for high-quality metal casting solutions. Specializing in high-precision metal sand mold casting, Runpeng Precision Hardware offers expert services using materials such as carbon steel, zinc alloy, and aluminum. Whether you need durable and accurate radiator components or other custom metal parts, our service is designed to meet your exact specifications with outstanding craftsmanship.

At Runpeng Precision Hardware, we understand the importance of precision and reliability in metal casting. Our customized die-casting service combines advanced technology with skilled workmanship to produce complex shapes and detailed parts that fit perfectly into your project. Using sand mold casting techniques, we ensure strong, high-quality pieces that can withstand tough conditions and provide lasting performance.

Our service is flexible and tailored to your specific needs. Whether you require small batches for prototypes or large-scale production runs, we can accommodate different order sizes without compromising on quality. By working closely with you throughout the process, we guarantee that the final product matches your design requirements, helping you reduce lead times and enhance productivity.

We work with a variety of materials to suit different applications. Carbon steel offers excellent strength and durability, making it ideal for heavy-duty parts. Zinc alloy is perfect for components that require corrosion resistance and good surface finish. Aluminum is lightweight and highly versatile, widely used in automotive and radiator parts for its excellent thermal conductivity. Whatever your material choice, our die-casting process delivers precise dimensions and smooth surfaces, minimizing the need for additional machining.

Runpeng Precision Hardware uses modern equipment and strict quality control measures to ensure every piece meets high standards. Our skilled team inspects each product carefully to confirm consistency, accuracy, and reliability. This attention to detail has earned us a strong reputation among clients who depend on us for their critical metal components.

The Customized Die-Casting Service by Runpeng Precision Hardware is an ideal solution for businesses seeking high-precision metal parts made from carbon steel, zinc alloy, or aluminum. With our expertise in sand mold casting and commitment to quality, we help you bring your ideas to life with parts that perform reliably in demanding environments. Choose Runpeng Precision Hardware for your next project and experience professional service, excellent craftsmanship, and exceptional results every time

Mold Material |

SKD61, H13 |

Cavity |

Single or multiple |

Mold Life Time |

50K times |

Product Material |

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

Surface Treatment |

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

Step, Dwg, Igs, Pdf |

Certificates |

ISO 9001:2015 & IATF 16949 |

Payment Term |

T/T, L/C, Trade Assurance |

800T die-casting machine |

1 |

630T die-casting machine |

1 |

400T die-casting machine |

2 |

300T die-casting machine |

1 |

280T die-casting machine |

2 |

180T die-casting machine |

1 |

2. We provide a competitive price

3. High precision, tolerance can be within ±0.01mm

4. 14 years' export experience

5. Small order also is welcomed

6. We provide one-stop service, including mold and assembly

7. All your information is confidential, and we can sign NDA as well

One-stop Solution

Quality Guarantee

Customer Service

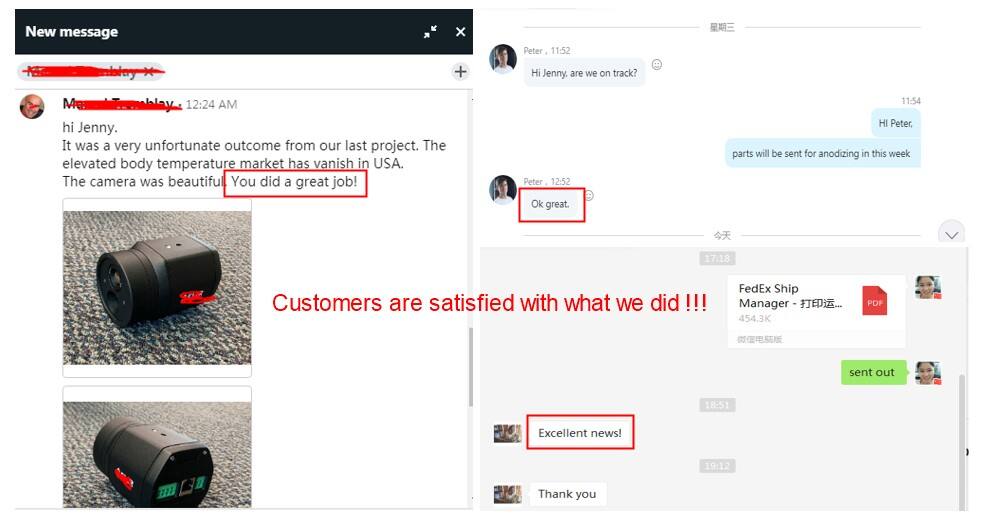

Our Regular Customer

Our Regular Customer

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, ChinaWelcome to visit our factory

Q2. What kind of production service do you provide

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment