- Overview

- Recommended Products

Introducing, the Customized Aluminum Alloy Die Casting Machines Parts Casting Motor Spare Part from Runpeng Precision Hardware. This high-quality spare part is designed to enhance the performance and longevity of your die casting machines.

Crafted from premium aluminum alloy, this spare part is both lightweight and durable. The die casting process ensures that each part is produced with precision and accuracy, resulting in a product that meets the highest industry standards. The aluminum alloy material exhibits excellent corrosion resistance and heat dissipation properties, making it ideal for use in demanding industrial environments.

The Customized Aluminum Alloy Die Casting Machines Parts Casting Motor Spare Part is customizable to suit your specific needs. With Runpeng Precision Hardware, you have the flexibility to choose the dimensions, shape, and surface finish of the part. Whether you require a custom-designed motor housing or a specific mounting bracket, we can tailor the spare part to meet your exact requirements.

The spare part is easy to install and compatible with a wide range of die casting machines. Its versatility makes it a valuable addition to any manufacturing or industrial operation. With Runpeng Precision Hardware, you can trust that your equipment will operate at optimal performance levels.

In addition to its functional benefits, the Customized Aluminum Alloy Die Casting Machines Parts Casting Motor Spare Part also boasts a sleek and modern design. The smooth finish and clean lines add a touch of sophistication to your machinery, enhancing its overall aesthetic appeal.

Invest in the Customized Aluminum Alloy Die Casting Machines Parts Casting Motor Spare Part from Runpeng Precision Hardware and experience the difference in quality and performance. Our commitment to excellence ensures that you receive a top-of-the-line product that meets your expectations and exceeds industry standards.

Upgrade your die casting machines with the Customized Aluminum Alloy Die Casting Machines Parts Casting Motor Spare Part from Runpeng Precision Hardware. Trust our expertise and craftsmanship to deliver a product that is reliable, durable, and built to last. Experience the difference today

Customized aluminum alloy die casting machines parts casting motor spare part

| Material | 1. Aluminum alloy ADC12, A380, A360, A356, A413, etc |

| 2. Zinc alloy 3#zinc, 5#zinc and 8#zinc, etc | |

| Designs | 1. As per the customer’s drawings |

| 2. As per the customer’s samples | |

| Surface treatment | 1. Sand blasting |

| 2. Power coating | |

| 3. Painting | |

| 4. Anodization | |

| 5. Electrophoresis | |

| 6. Zinc/Chrome/Nickel plating | |

| 7. Black oxidation | |

| Software | Pro/E, Auto CAD, CAXA UG, CAD |

| Service | OEM service available |

| Products | All kinds of aluminum &zinc alloy casting: include automotive parts, monitor parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts, and so on |

| Inspection | 1. Foundry in-house: 100% inspection on critical dimension; 100% on appearance |

| 2. Third Party inspection available upon requirement | |

| Packing | Single protective + Carton + Pallet, each carton less than 15KG |

| Payment | T/T, L/C |

Die casting machine |

150T 2 sets |

| 180T 1 set | |

| 280T 1 set | |

| 400T 1 set | |

| 800T 1 set | |

Secondary equipments |

Three-axis CNC machine 4 sets |

Four-axis CNC machine 2 sets | |

Numerical-controlled Lathe 8 sets | |

Drilling and tapping machines 4 sets | |

Tapping machines 12 sets | |

Drilling machines 20 sets | |

Lathes, horizontal 10 sets | |

Drilling-machines, multi-spindle 1 set | |

Milling machines, vertical 2 sets | |

Punching machines |

120T punch 1 set |

100T punch 1 set | |

65T punch 2 sets | |

40T punch 1 set | |

25T punch 2 sets | |

15T punch 2 sets | |

Bending machines 2 sets | |

Shearing machines 2 sets | |

CNC Punching machines 1 set | |

Injection Department |

250T Injection machine 1 set |

200T Injection machine 1 set | |

150T Injection machine 1 set | |

80T Injection machine 2 sets | |

Inspection equipments |

CMM 1 set |

Pneumatic ID measuring head & counter gauge 1s et | |

Callipers 30 sets | |

Altitude gauge 2 sets | |

Hardness Gauge 1 set | |

Thread gauge 30 sets | |

Micrometer 2 sets |

| 20 YEARS experience in manufacturing Die casting | |

| Our advantage | 1) We are a professional OEM die casting manufacturer |

| 2) We have an experienced engineer and quality control team as our strong backing | |

| 3) High quality, competitive price, quick response is our mission | |

| 4) Professional technical support | |

| 5) Quick response | |

| 6) Strict quality control process | |

| 7) High cost performance | |

| 8) Rich experience in mould design and die casting | |

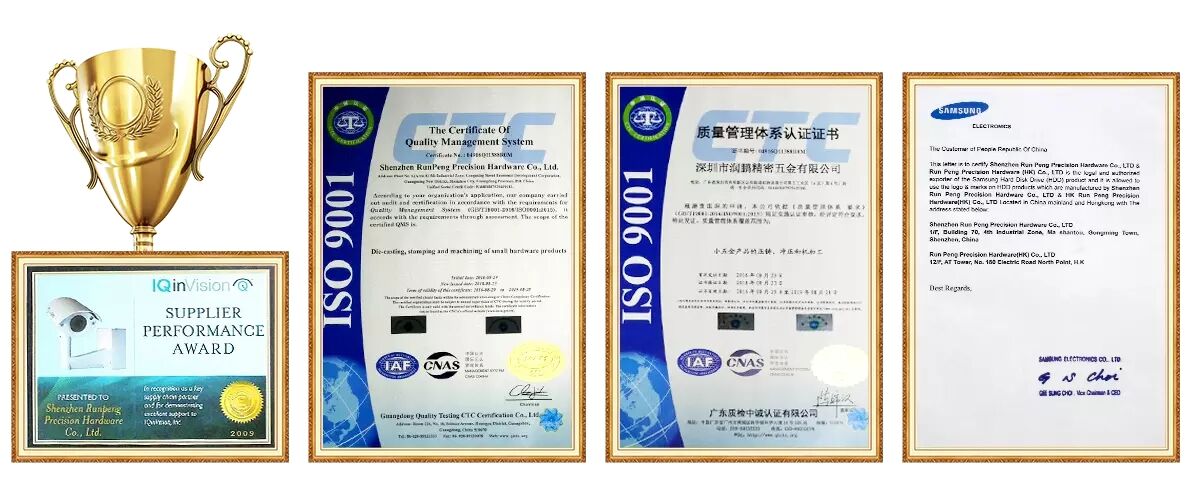

| 8) ISO/ERP sysytem guarantee | |

| We can also provide | 1) Stamping |

| 2) CNC Machining | |

| 3) Extrusion | |

| 4) Plastics Injection | |

Customers are from all over the world

we are from RunPeng in China, thanks for let us to share with you a short overview of our activities:

1. Rapid Prototype Service

CNC Machining, SLA(Stereolithography) and SLS(Selective Laser Sintering), 4~7days lead time.

2. CNC machining Service

Specialized in CNC turning, 4-axis CNC milling, 5-axis CNC machining, and complex CNC turning&milling

3. Mold Making Service

We export Molds for problem-free use, and also make economical molds for use in China-we also have the injection machines for molding production.

4. Parts Production, Final Assembly, Testing and Packaging service

To further reduce your cost we produce plastic and metal parts in China further. Assembly is generally the most labor intensive step in the production process, so this is really where we can save you a lot as well.

If you have any projects that you feel proper for RunPeng, please send your 3D file to us for prices. thank you

CASE SHOW:

from Rapid Prototype-->tooling--->Final Production

rapid prototype and CNC machined parts from clients' own design