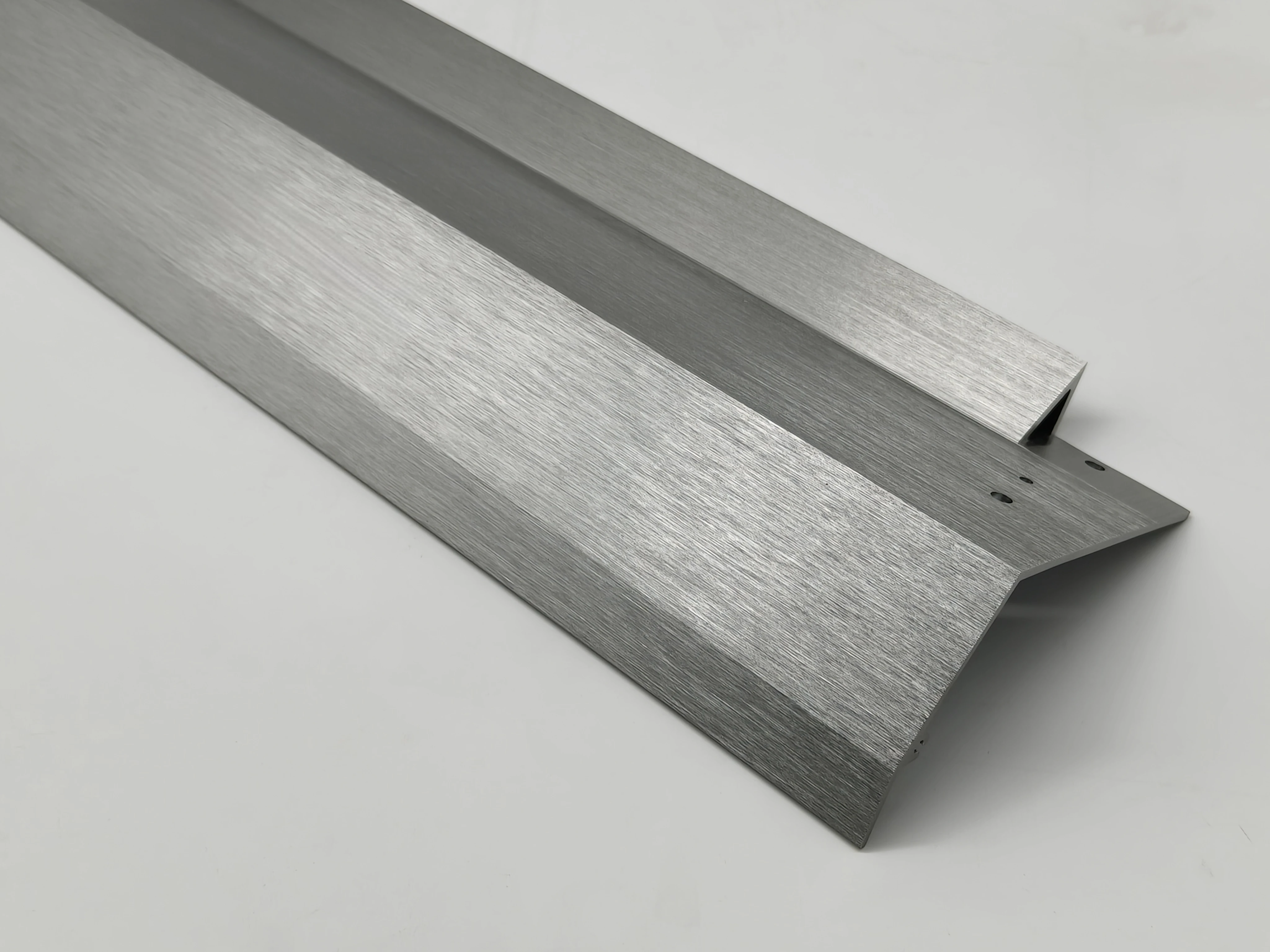

OEM Provides Drawing for Processing; Precision Aluminum Alloy Stamping Machine Cabinet Frame Bracket with Sheet Metal Bending

- Overview

- Recommended Products

Runpeng Precision Hardware proudly presents our OEM service for precision aluminum alloy stamping machine cabinet frames and brackets. Designed to meet your exact needs, we provide detailed drawings for processing to ensure every piece matches your requirements perfectly. Whether you're creating a new product or need replacement parts, our team works closely with you from start to finish to deliver high-quality components that fit right the first time.

Our precision aluminum alloy stamping products are made using advanced techniques that combine stamping and sheet metal bending. This combination allows us to create strong, durable, and lightweight parts that perform well in demanding environments. Aluminum alloy is chosen for its excellent strength-to-weight ratio and corrosion resistance, making it an ideal material for machine cabinet frames and brackets that need to last and maintain stability over time.

At Runpeng Precision Hardware, quality is at the heart of everything we do. Our stamping process uses modern machinery that ensures consistent accuracy and smooth finishes on every part. The bending process adds flexibility to the design, allowing complex shapes and angles that standard cutting and welding can’t achieve without weakening the metal. This means your machine cabinet frames and brackets are robust and have a professional appearance.

We understand that every project is unique. That’s why our OEM service includes providing detailed drawings before production begins. These drawings allow you to review and approve the exact specifications, dimensions, and design features. Creating precise drawings helps us avoid errors, reduces production time, and ultimately saves you money. Plus, it gives you confidence that the final product will meet your standards.

Runpeng Precision Hardware is dedicated to delivering excellent customer service alongside superior products. Our team is available to help with technical advice, adjustments to design, and fast turnaround times. Whether you require small batches or large volume production runs, we tailor our service to your needs.

If you need precision aluminum alloy stamping machine cabinet frames or brackets made with sheet metal bending, Turn to Runpeng Precision Hardware. Our OEM drawing services ensure your components are manufactured exactly as you envision, combining strength, precision, and quality in every piece. Contact us today to discuss your project and experience the Runpeng difference

Mold Material |

Cr12 |

Mold Life Time |

300K times |

Product Material

|

1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L

4) SPTE, galvanized sheet

5) Brass, copper

|

Surface Treatment |

Anodized, powder coating, lacquer coating, black oxide |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

Step, Dwg, Igs, Pdf |

Certificates |

ISO 9001:2015 & IATF 16949 |

Payment Term |

T/T, L/C, Trade Assurance |

160T punching machine |

1 |

110T punching machine |

2 |

60T punching machine |

3 |

40T punching machine |

1 |

Hydraulic shearing machine |

2 |

Hydraulic rivet machine |

1 |

One-stop Solution

Quality Guarantee

Customer Service

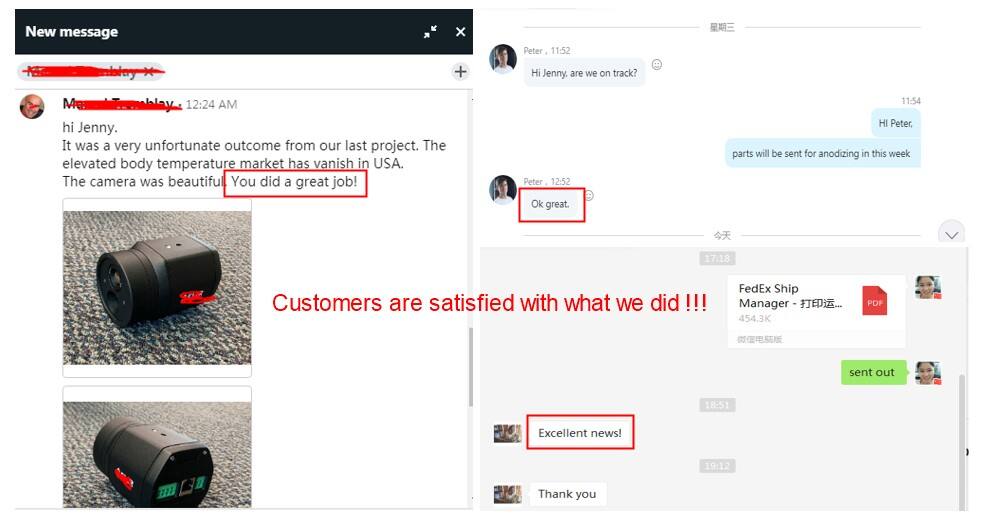

Our Regular Customer

Our Regular Customer

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years' export experience.

5. Small order also is welcomed.

6. We can also provide one-stop service, including mold and assembly.

7. All samples will be inspected by CMM before shipment, and also each step process will be controlled by CMM

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, ChinaWelcome to visit our factory

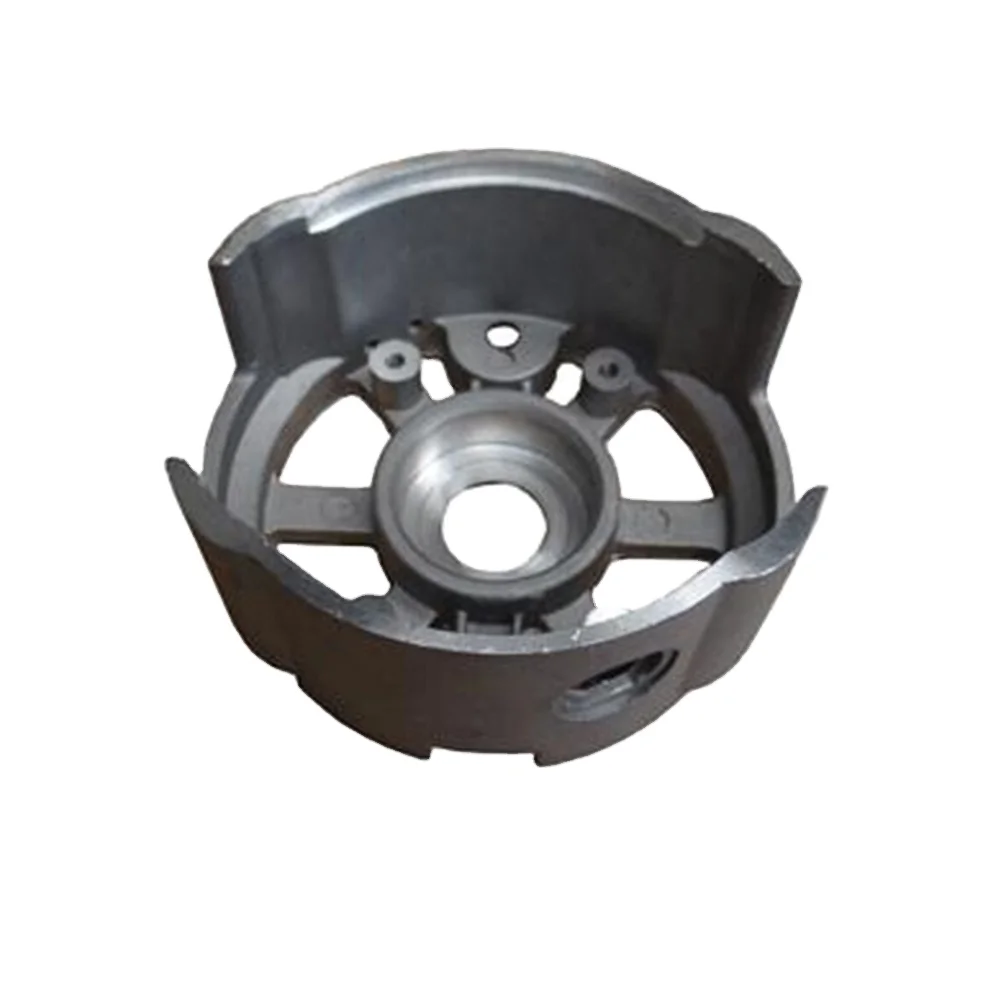

Q2. What kind of production service do you provide

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment