- Overview

- Recommended Products

Introducing, the Runpeng Precision Hardware OEM Aluminum Alloy Mechanical Equipment Parts with Anodizing Surface Treatment Casting Service. This high-quality product is perfect for those in need of durable and reliable mechanical equipment parts for various applications.

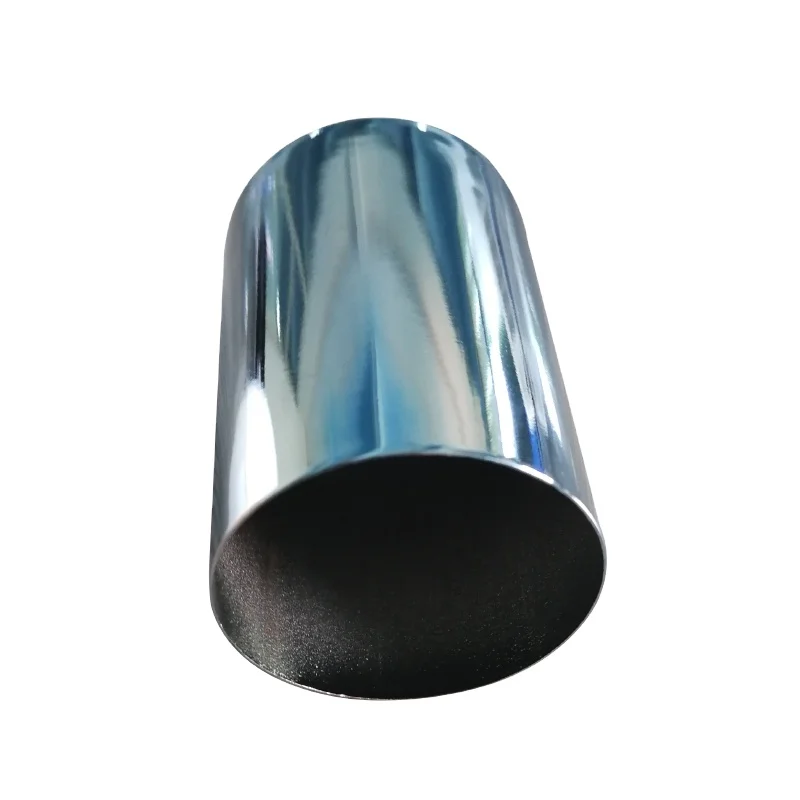

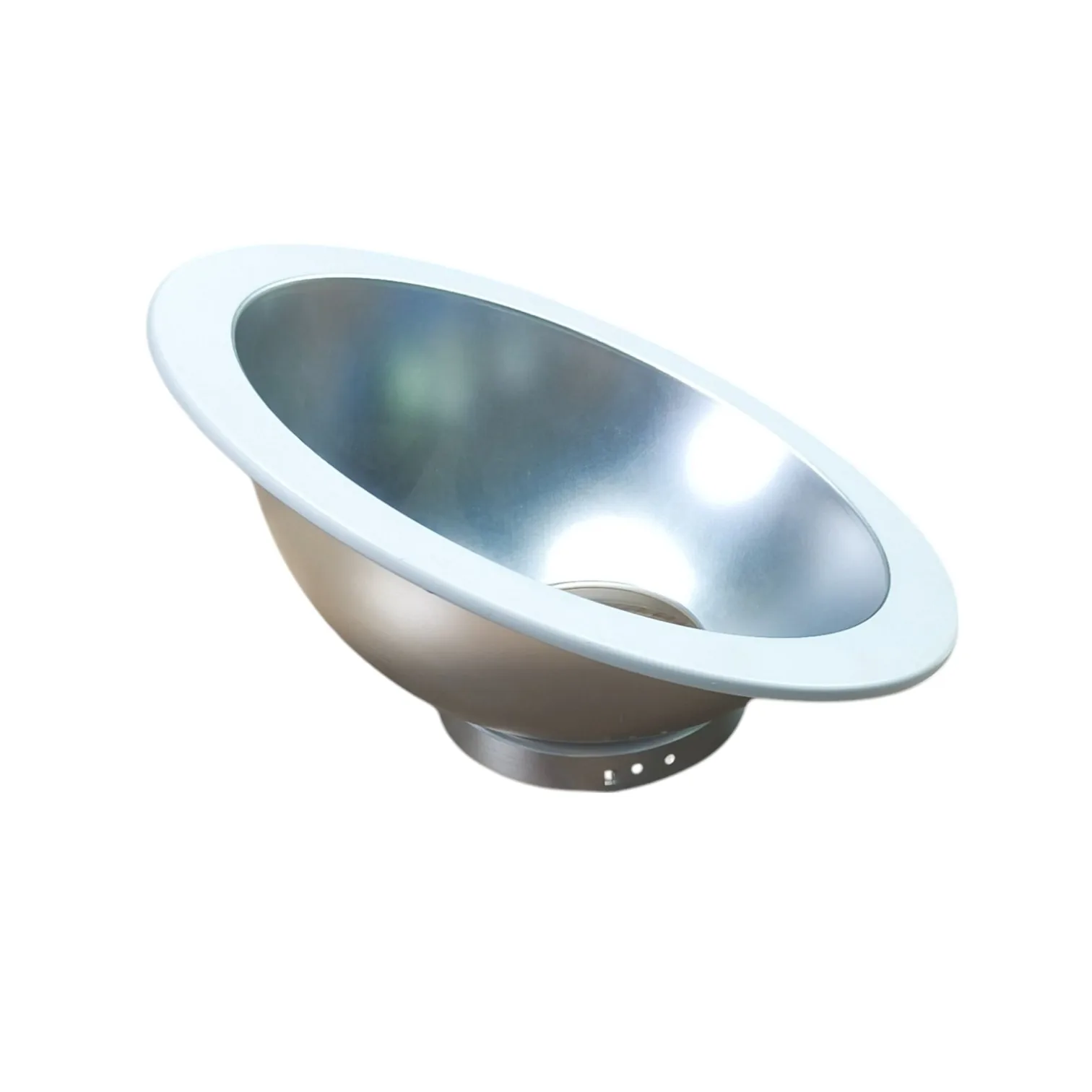

Crafted from premium aluminum alloy, these parts are sturdy and long-lasting, ensuring they can withstand even the most demanding conditions. The anodizing surface treatment adds an extra layer of protection, preventing corrosion and wear over time. This not only extends the lifespan of the parts but also maintains their aesthetic appeal.

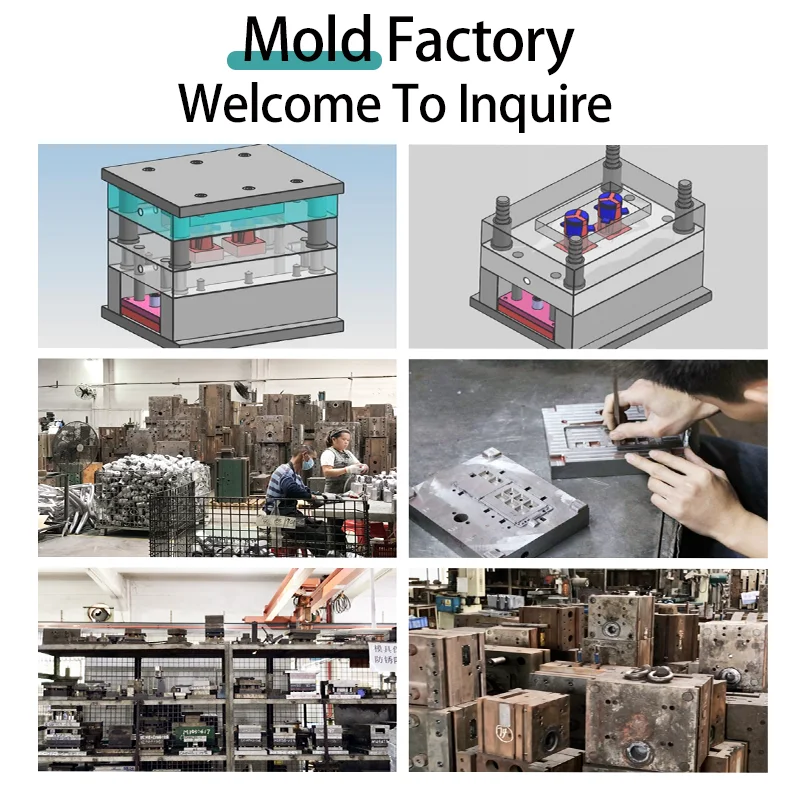

What sets Runpeng Precision Hardware apart is their commitment to providing top-notch casting services. The parts are meticulously crafted using advanced technology and machinery, ensuring precision and accuracy in every piece produced. This attention to detail guarantees that each part meets the exact specifications and requirements of the customer.

Whether you are in the automotive, aerospace, or industrial sector, these OEM aluminum alloy mechanical equipment parts are versatile and can be customized to suit your specific needs. From small components to larger structural parts, Runpeng Precision Hardware has the capabilities to deliver high-quality products that meet industry standards.

In addition to their exceptional quality, Runpeng Precision Hardware prides itself on offering competitive pricing and efficient lead times. This makes them an ideal partner for businesses looking to streamline their production processes and reduce costs without compromising on quality.

When you choose the Runpeng Precision Hardware OEM Aluminum Alloy Mechanical Equipment Parts with Anodizing Surface Treatment Casting Service, you can trust that you are investing in a product that is built to last. With their superior craftsmanship, attention to detail, and commitment to customer satisfaction, you can have peace of mind knowing that you are getting the best value for your money.

Upgrade your mechanical equipment with Runpeng Precision Hardware and experience the difference in quality and performance. Choose reliability, durability, and precision with Runpeng Precision Hardware OEM Aluminum Alloy Mechanical Equipment Parts

Mold Material |

SKD61, H13 |

Cavity |

Single or multiple |

Mold Life Time |

50K times |

Product Material |

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

Surface Treatment |

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

Step, Dwg, Igs, Pdf |

Certificates |

ISO 9001:2015 & IATF 16949 |

Payment Term |

T/T, L/C, Trade Assurance |

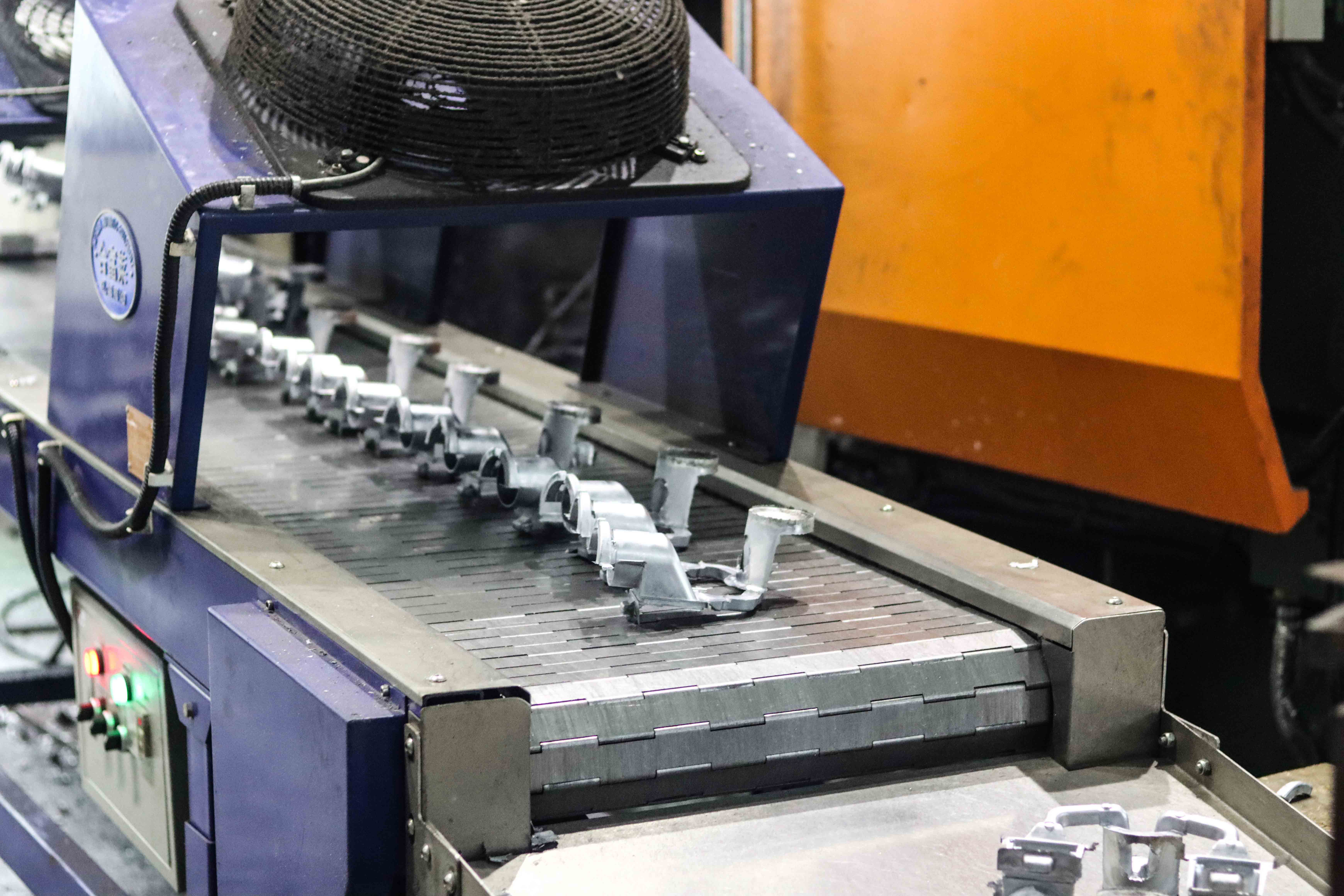

800T die-casting machine |

1 |

630T die-casting machine |

1 |

400T die-casting machine |

2 |

300T die-casting machine |

1 |

280T die-casting machine |

2 |

180T die-casting machine |

1 |

One-stop Solution

Quality Guarantee

Customer Service

Our Key Customer

We have cooperated since 2007. Annual order more than $1.2 million

Our Regular Customer

Our Regular Customer

Our Regular Customer

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China. Welcome to visit our factory

Q2. What kind of production service do you provide

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

Q6. What is your quotation element

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment