- Overview

- Recommended Products

Runpeng Precision Hardware

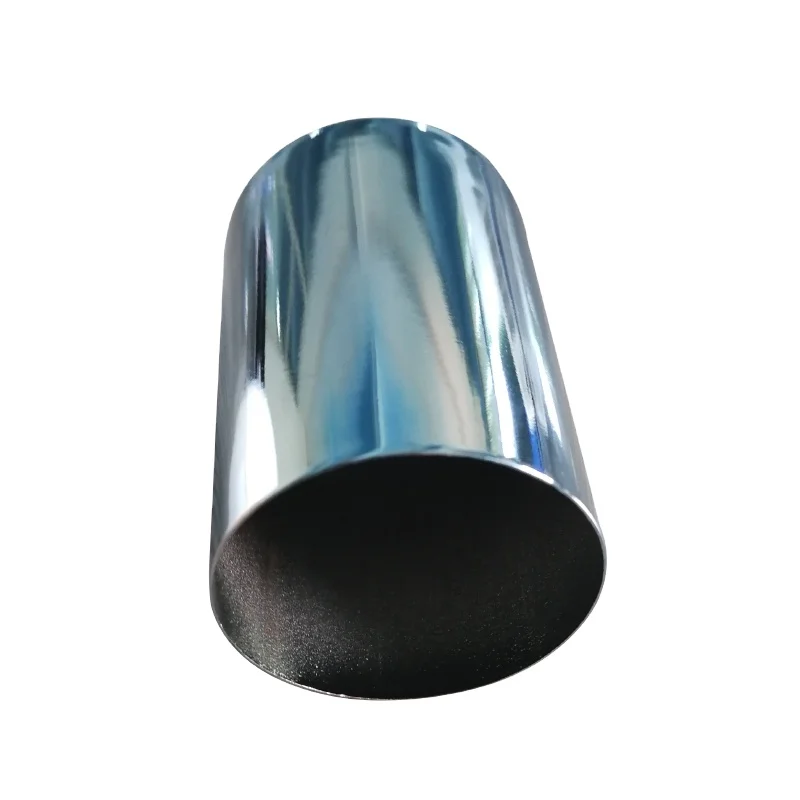

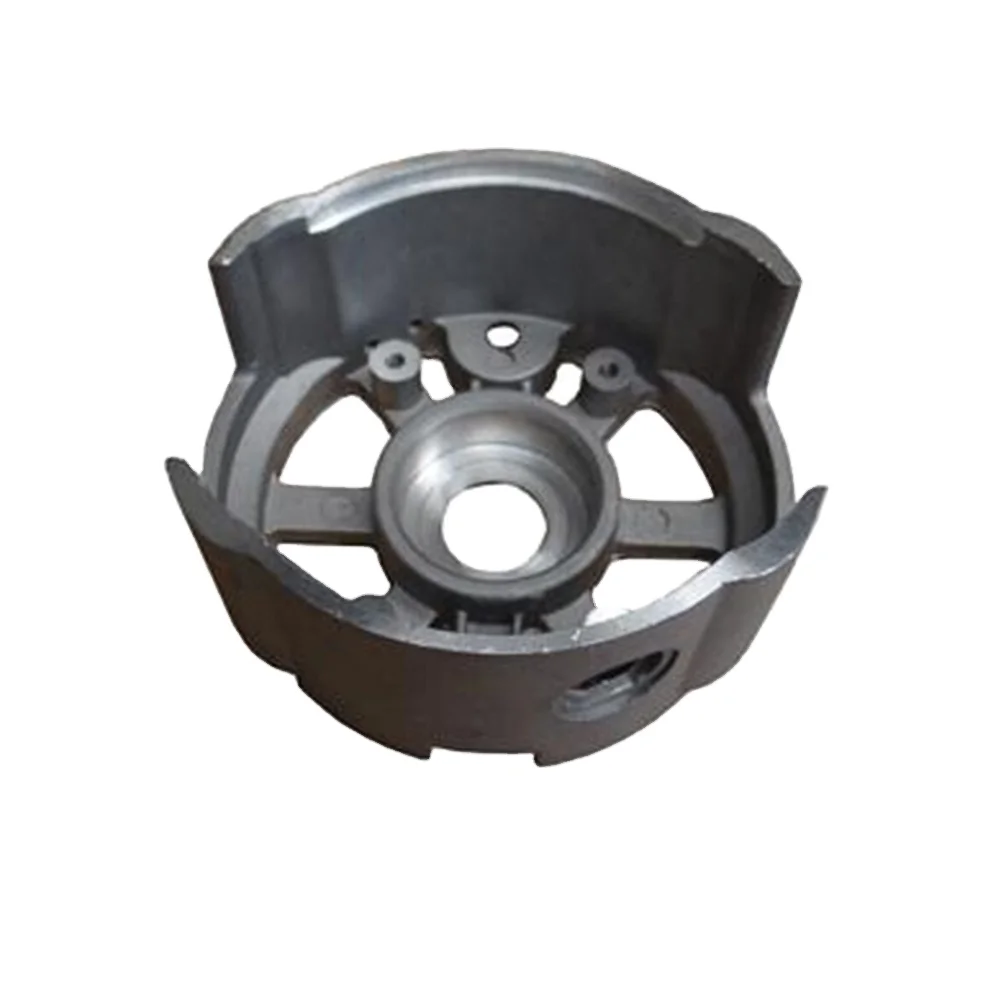

Introducing Runpeng Precision Hardware's custom deep drawing sheet metal fabrication tools for all your sheet metal forming needs. Our top-of-the-line tools are carefully designed and crafted to provide precise and efficient results every time.

Our sheet metal fabrication tools are perfect for creating a wide range of products, from simple shapes to complex designs. Whether you're working on a small project or a large-scale production, our tools are up to the task.

Made from high-quality materials, our custom deep drawing sheet metal fabrication tools are built to last. With durable construction and expert craftsmanship, you can Runpeng Precision Hardware rely on our tools to deliver consistent performance day after day.

These tools are designed for ease of use, making them suitable for both experienced professionals and beginners. With user-friendly features and a simple operation, you can quickly and easily create the perfect shapes and forms for your projects.

Our custom deep drawing sheet metal fabrication tools are versatile and can be used for a variety of applications. Whether you're working with aluminum, steel, copper, or any other type of metal, our tools can handle the job with precision and accuracy.

At Runpeng Precision Hardware, we are committed to providing our customers with the highest quality products and exceptional service. Our custom deep drawing sheet metal fabrication tools are a testament to this commitment, offering superior performance and reliability at an affordable price.

Whether you're a hobbyist or a professional fabricator, our sheet metal forming tools are the perfect choice for your next project. Trust in Runpeng Precision Hardware to provide you with the tools you need to bring your ideas to life.

Invest in quality and precision with our custom deep drawing sheet metal fabrication tools. Experience the difference that Runpeng Precision Hardware can make in your sheet metal forming projects. Order yours today and see the results for yourself.

Mold Material |

Cr12 |

Mold Life Time |

300K times |

Product Material

|

1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L

4) SPTE, galvanized sheet

5) Brass, copper

|

Surface Treatment |

Anodized, powder coating, lacquer coating, black oxide |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

step, dwg, igs, pdf |

Certificates |

ISO 9001: 2015 & IATF 16949 |

Payment Term |

T/T, L/C, Trade Assurance |

160T punching machine |

1 |

110T punching machine |

2 |

60T punching machine |

3 |

40T punching machine |

1 |

Hydraulic shearing machine |

2 |

Hydraulic rivet machine |

1 |

One-stop Solution

Quality Guarantee

Customer Service

Our Regular Customer

Our Regular Customer

Our Regular Customer

Our Regular Customer

Our Regular Customer

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years' export experience.

5. Small order also is welcomed.

6. We can also provide one-stop service, including mold and assembly.

7. All your information is confidential, and we can sign NDA as well.

Q1. Are you a factory or trade company?

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China

Welcome to visit our factory.

Q2. What kind of production service do you provide?

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment.

Q3. How about the lead time?

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got ISO9001: 2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days

Q6. What is your quotation element?

Drawings or Sample, Material, Finish, and Quantity.

Q7. What is your payment term?

Mold: 50% prepaid, balance after sample approval.

Goods: 50% prepaid, balance T/T before shipment