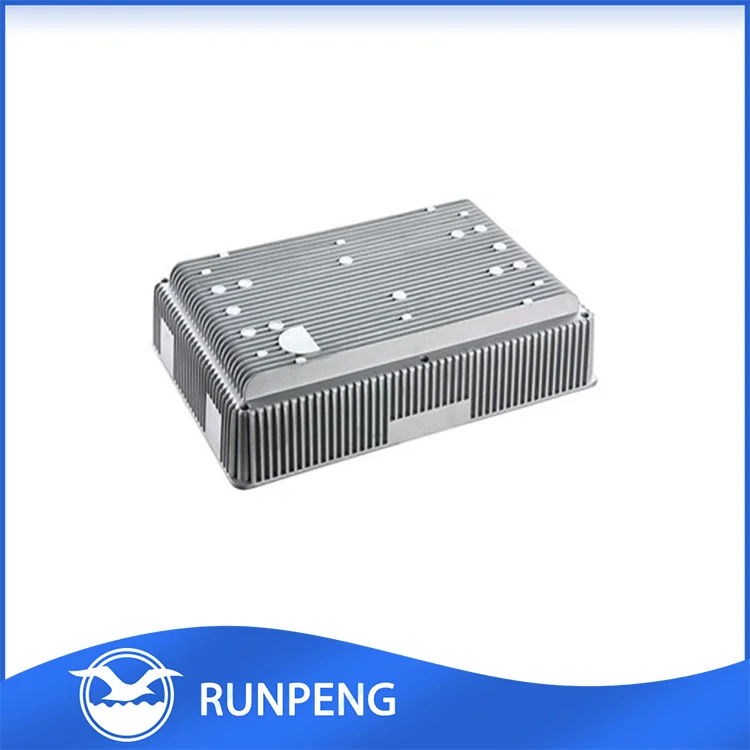

For low-volume manufacturers and metal part makers who have spent decades pondering and struggling with just how to make metal parts in small amounts, there’s one straightforward question: how to do it inexpensively and efficiently. One popular solution is stamping. Stamping is the method of transforming metal by pressing into a mold or die. It’s a super quick and extremely accurate method that’s perfect to fire off some high quality metal parts and not spend all the money. Runpeng Precision Hardware, we realize the importance of cost-effective production methods such as stamping for low-volume manufacturers

The number one reason behind the use of stamping for low volume manufacturers

Stamping is a cost saving measure that low-volume manufacturers opt for. “When you’re producing less product, you need something that doesn’t cost a lot but still works really well. Stamping requires no special equipment or setups beyond the loom, which is costly. Rather, you can make a bunch of parts really quickly with one mold or die. This translates to spending less money to make each part, which matters a great deal to manufacturers that don't turn out huge volumes

How Stamping Ensures Uniform Quality in Fabrication of Metal Parts

Stamping is ideal when you want to be certain every metal part is exactly right. With a stamping die, every piece is the same. It’s especially crucial when you want all your parts to look the same and work together smoothly, like in machines or things people use every day. Our customers can depend on us to provide top-of-the-line parts using the stamping process at Runpeng Precision Hardware

How Low-Volume Manufacturers can Benefit from Stamping Technology

And while it’s already cheaper for some to get ahead by hot stamping, the tech has more cool stuff going for it. It’s very fast, so you can make parts quickly and you can deliver quickly. It also comes in many other flavors of metal, so manufacturers are not limited to only one kind. And it’s a clean process with less waste, which is better for our planet. These advantages make stamping the ideal choice for smaller manufacturers who want to remain competitive and eco-conscious

Benefits of Stamping in Manufacturing Metal Parts for Small Batch Operations

Stamping offers particular benefits for small scale production. It lets these smaller manufacturers play big. Because stamping is so versatile, it can be used in a wide range of projects. Whether they have to produce basic parts or more intricate ones, stamping can do it. This flexibility enables small businesses to expand without requiring too many extra resources, resources that very well could be more than they could handle

Low-Volume Manufacturers and the Cost Savings of Stamping Production Methods

Cost savings is a huge benefit for stamping low-volume manufacturers. They cut labor costs by relying on stamping bracket machines to do the majority of the work. They also don’t need to stockpile as many raw materials, reducing costs. And the speed at which they can set up and start producing parts allows them to respond more quickly to customer orders without additional costs. For small manufacturers that need to turn a profit and keep the doors open, such savings are make or break

Runpeng Precision Hardware understands the importance of these advantages. We’re stampers because it allows us, and our customers, to produce high-quality metal parts in an efficient and cost-effective manner. We use it every day, whether it’s a large job or a small one, stamping is definitely a primary tool for us in our manufacturing process

Table of Contents

- The number one reason behind the use of stamping for low volume manufacturers

- How Stamping Ensures Uniform Quality in Fabrication of Metal Parts

- How Low-Volume Manufacturers can Benefit from Stamping Technology

- Benefits of Stamping in Manufacturing Metal Parts for Small Batch Operations

- Low-Volume Manufacturers and the Cost Savings of Stamping Production Methods