Selecting the Right Wholesale CNC Cutting Technology For Your Business

The right sheet metal cutting services for your wholesale business When it comes to selecting the ideal CNC cutting service for your wholesale business, how do you choose between laser vs. Shipping Information. Each of these technologies has their own advantages and disadvantages, so it is best to know the different before you decide. With laser cutting, a high-powered laser cuts material in intricate patterns or details. By contrast, plasma cutting employs an ionized gas to blow through materials at a high velocity, making it faster and more cost-efficient for thicker materials. Factor in what type of material you will be working with, and also the intricacy of your projects and know how much money your going to be spending when deciding laser cutting or plasma cutter for wholesale.

So, you have concluded that laser cutting is the best bet for a wholesale business and now, you must find a dependable and inexpensive service provider. Factors to Consider When Choosing a Laser Cutting Service for Wholesales: We will consider the price, turnaround time and comments of customer when you purchase in bulk. There may also be a bulk order discount or wholesale rate offer available from some companies, so ask if you’re considering large orders. Through collaboration with a destination laser cutting supplier like Runpeng Precision Hardware, you can rest easy that your wholesale items are cut perfectly and accurately.

The selection of the appropriate CNC cutting method for your products.

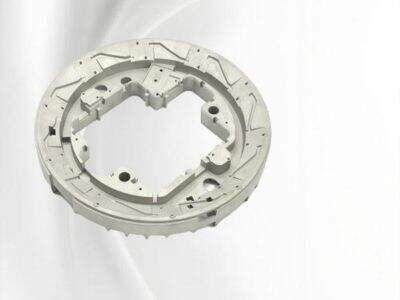

There are a lot of things to be considered when deciding between laser cutting or plasma cutting for CNC cutting services. Laser cutting is a high-speed, massively accurate cutting process ideal for cutting complex shapes and thin materials. On the contrary, Runpeng Precision Hardware cnc aluminum cutting is a more rapid and economical technique with better performance for thick materials.

To find the best CNC cutting solution for your model, think about the material you are going to cut with. If you are dealing with thinner materials which demand high quality cuts, then laser cutting will be ideal for you. But when it comes to thicker materials and price is an issue, then plasma cutting could be the answer.

Also think about your project’s volume of production and timing as well. Laser cutting is substantially faster than plasma cutting, so if you’re in a hurry, it can be the better option. But, if you need to cut tons of product and price is an issue, plasma cutting could be a better fit.

Wholesale buyers guide to the differences between plasma and laser cutting.

As a wholesale buyer considering which of the plasma cutting and laser cutting for CNC cutting to make use of, you have to take into account if your customers need certain kind of finishes. Laser cutting is a great method for intricate and fiddly parts that require high quality finishes. Runpeng Precision Hardware die-casting is more suitable for thicker materials and can cut faster.

There are certain things you’ll need to think about when deciding whether to choose plasma cutting or laser cutting. If you have thinner materials that need to be cut with extreme precision, laser cutting will be your best choice. But if you’re cutting through thicker materials and have a large number of items to produce in a short period, then plasma cutting is the right choice.

Top Questions to Ask while Choosing between Laser and Plasma Cutting Services.

When you are trying to compare laser and plasma cutting with regards to services for CNC-cutting, it is essential that you ask certain questions. The very first thing to determine is what will you be cutting and how precise does it need to be. It is more accurate than plasma cutting, so if you have a challenging design laser cutting may be the best choice.

Second, look at the production volume and scale of your project. It’s faster than the plasma cutting process and so if you’re working on a tight schedule, or have to put out a lot of product quickly, laser cutting may be your best bet. Finally, of course, you will want to think about the cost of each cutting method and how it works within your budget.

So then, which technique is best for you? When deciding between laser cutting and plasma cutting services for your CNC cutting needs, there are a few factors to consider specific to the products you need help producing, your production volume, timeline and budget. These aspects should be carefully considered to decide on the most suitable cutting process for your company. Don't forget that we also provide Runpeng Precision Hardware cnc cutting services and plasma cutting to satisfy all of your CNC cutting requirements.