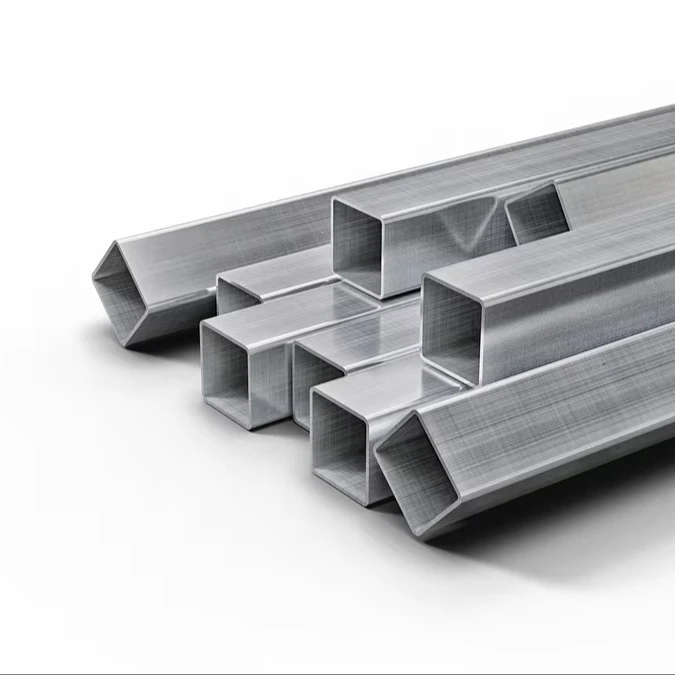

Super Quality Custom All Kinds of Aluminum Extrusion Profiles Factory Price 6061 6063 Square Aluminum Profile

- Overview

- Recommended Products

Introducing, the Runpeng Precision Hardware Super Quality Custom Aluminum Extrusion Profiles! Our factory offers a wide range of options including the popular 6061 and 6063 Square Aluminium Profile. These profiles are perfect for a variety of projects and applications, providing durability and reliability at an affordable price.

At Runpeng Precision Hardware, we are dedicated to producing high-quality products that meet the needs of our customers. Our custom aluminum extrusion profiles are made with precision and care, ensuring that each piece meets our strict quality standards. Whether you need a specific size, shape, or finish, we can create the perfect profile for your project.

Our extrusion profiles are made from top-quality materials, offering excellent strength and corrosion resistance. This makes them ideal for use in a wide range of industries, from construction to automotive to electronics. No matter the application, you can trust that our profiles will provide the performance and reliability you need.

In addition to their quality construction, our aluminum profiles are also designed for easy installation and assembly. This means you can save time and effort when using our products, helping you complete your projects quickly and efficiently. Plus, with our competitive factory prices, you can get the quality you need without breaking the bank.

Whether you are a DIY enthusiast, a professional contractor, or a manufacturer, the Runpeng Precision Hardware Super Quality Custom Aluminum Extrusion Profiles are the perfect choice for your next project. With their durable construction, versatile design, and affordable price, these profiles offer everything you need to get the job done right.

Don't settle for subpar products – choose the best with Runpeng Precision Hardware! Contact us today to learn more about our Super Quality Custom Aluminum Extrusion Profiles and place your order. Experience the difference that quality and precision can make in your projects with Runpeng Precision Hardware

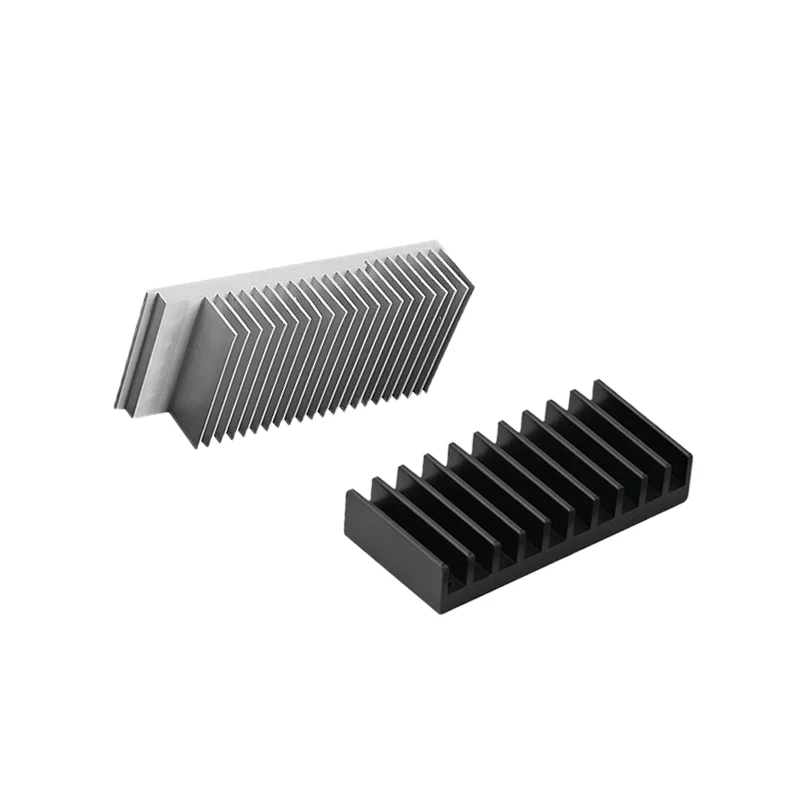

Custom Aluminum Heat Sink, Aluminum Heat Sink For LED

Product Details:

| Mold Material | H13 |

| Mold Life Time | 500K times |

| Product Material | AL6061, AL6063 |

| Surface Treatment | Anodized, powder coating, lacquer coating, sandblast |

| Size |

1) According to customers' drawings 2) According to customers' samples |

| Drawing Format | step, DWG, IGS, pdf |

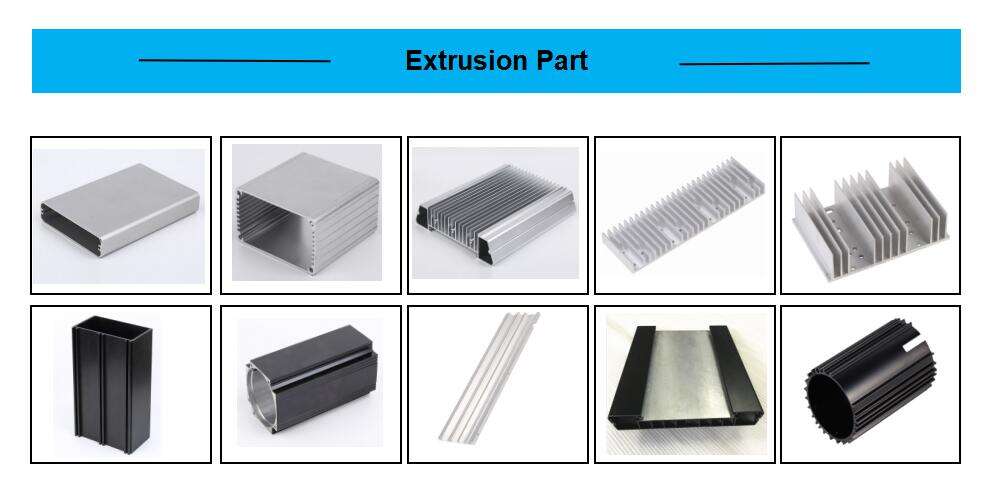

Click Here For More Extrusion Part

More than 26 YEARS experience in manufacturing mold, die casting, stamping, CNC machining, extrusion, and plastic injection parts

More Information:

1. Packing: polybag, carton, pallet

2. Tooling payment term: 50% deposit with the PO, and balance after sample approving

3. Price term: EXW, FOB, CIF and so on

4. FOB port: Shenzhen or HK

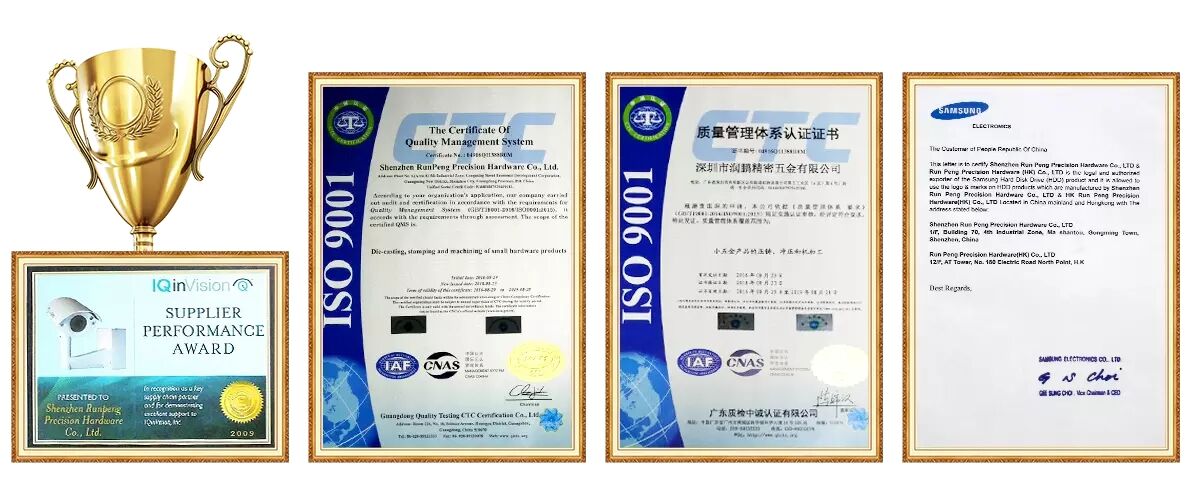

5. Certification: ISO 9001:2015 & IATF 16949

6. Warranty: 2 years

Advantages:

1. Own factory and 80% of staff in our company worked for more than 10 years

2. We provide a competitive price

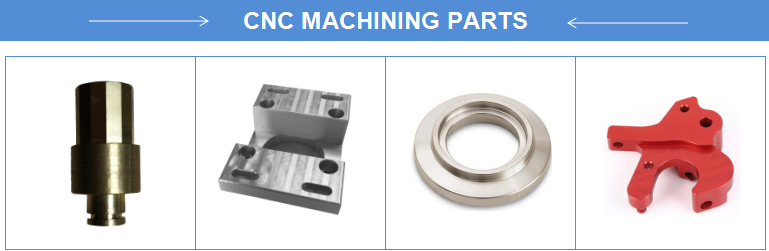

3. High precision, tolerance can be within ±0.01mm

4. 14 years' export experience

5. Small order also is welcomed

6. We can also provide one-stop service, including mould and assembly

7. All samples will be inspected by CMM before shipment, and also each step process will be controlled by CMM

| Company Information | |

| 26 YEARS factory | |

| Our advantage | 1) We are a professional OEM stamping, die casting and CNC Machining manufacturer |

| 2) We have an experienced engineer and quality control team as our strong backing | |

| 3) High quality, competitive price, quick response is our mission | |

| 4) Professional technical support | |

| 5) Quick response | |

| 6) A strict quality control process | |

| 7) High-cost performance | |

| 8) Rich experience in mould design and die casting | |

| 9) ISO/ERP system guarantee | |

| We can also provide | 1) Die Casting |

| 2) CNC Machining | |

| 3) Stamping | |

| 4) Extrusion | |

| 5) Plastic Injection | |

| Our equipments: | |

| Die casting machine | 150T 2sets |

| 180T 2set | |

| 280T 2set | |

| 400T 1set | |

| 800T 1set | |

| Secondary equipments | Three-axis CNC machine 4sets |

| Four-axis CNC machine 2sets | |

| Numerical-controlled Lathe 8sets | |

Drilling & tapping machines 4sets | |

| Tapping machines 12sets | |

| Drilling machines 20sets | |

| Lathes, horizontal 10sets | |

| Drilling-machines, multi-spindle 1set | |

| Milling machines, vertical 2sets | |

| Punching machines | 120-160T punch 2set |

| 100T punch 1set | |

| 65T punch 2sets | |

| 40T punch 1set | |

| 25T punch 2sets | |

| 15T punch 2sets | |

| Bending machines 2sets | |

| Shearing machines 2sets | |

| CNC Punching machines 1set | |

| Injection Department | 250T Injection machine 1 set |

| 200T Injection machine 1set | |

| 150T Injection machine 1set | |

| 80T Injection machine 2sets | |

| Inspection equipments | CMM 1set |

| Pneumatic ID measuring head & counter gauge 1set | |

| Callipers 30sets | |

| Altitude gauge 2sets | |

| Hardness Gauge 1set | |

| Thread gauge 30sets | |

| Micrometer 2 sets | |

Customers are from all over the world

Q1. Are you a factory or trade company

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China Welcome to visit our factory

Q2. What kind of production service do you provide

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 2 days

Q6. What is your quotation element

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment