- Overview

- Recommended Products

Introducing, the Custom Brass Die Cast Copper Casting Part from Runpeng Precision Hardware. This top-of-the-line product is expertly crafted with precision and made to last. Whether you are in need of a specific replacement part or looking to enhance the functionality and appearance of your machinery, this custom casting part is the perfect solution.

Constructed from high-quality brass, this die cast copper casting part is not only durable but also corrosion-resistant, ensuring longevity and reliable performance. The precision machining ensures a perfect fit for your machinery, eliminating the need for adjustments or modifications. Each part is meticulously inspected to meet the strict quality standards set by Runpeng Precision Hardware.

The custom brass die cast copper casting part is versatile and can be used in a wide range of applications including automotive, aerospace, electronics, and more. Its versatility makes it a must-have for any industry where precision and durability are essential. Whether you are replacing a worn-out part or upgrading your machinery, this custom casting part will exceed your expectations.

In addition to its exceptional quality and durability, this product is also highly customizable. Runpeng Precision Hardware understands that every customer has unique needs and specifications, which is why they offer customization options to suit your specific requirements. From size and shape to finish and color, you can customize this casting part to meet your exact specifications.

With Runpeng Precision Hardware's reputation for excellence in the industry, you can trust that this custom brass die cast copper casting part is made with the highest standards of craftsmanship and quality control. You can have peace of mind knowing that you are investing in a product that is built to last and perform at its best.

The Custom Brass Die Cast Copper Casting Part from Runpeng Precision Hardware is a superior product that offers durability, precision, and customization options. Whether you are in need of a replacement part or looking to upgrade your machinery, this custom casting part is the perfect choice. Trust in the quality and reliability of Runpeng Precision Hardware and experience the difference with this exceptional product

Mold Material |

SKD61, H13 |

Cavity |

Single or multiple |

Mold Life Time |

50K times |

Product Material |

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

Surface Treatment |

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

Size |

1) According to customers' drawings 2) According to customers' samples |

Drawing Format |

step, Dwg, Igs, pdf |

Certificates |

ISO 9001:2015 & IATF 16949 |

Payment Term |

T/T, L/C, Trade Assurance |

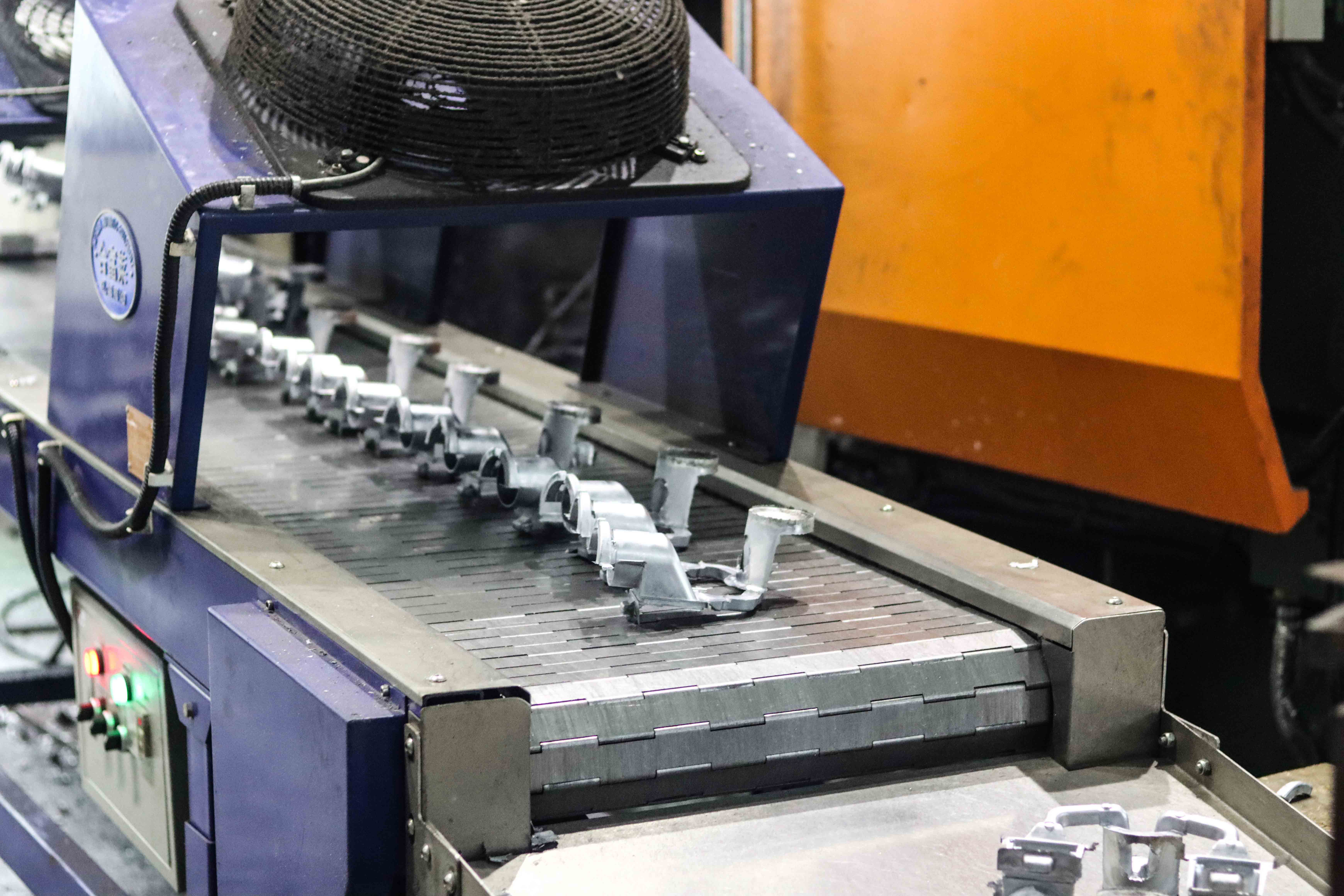

800T die-casting machine |

1 |

630T die-casting machine |

1 |

400T die-casting machine |

2 |

300T die-casting machine |

1 |

280T die-casting machine |

2 |

180T die-casting machine |

1 |

One-stop Solution

Quality Guarantee

Customer Service

Our Key Customer

We have cooperated since 2007

Annual order more than $1.2 million

Our Regular Customer

Our Regular Customer

Our Regular Customer

Our Regular Customer

Q1. Are you a factory or trade company

We are a factory located in 6th Building, No 51, Nanhuan Ave, Gongming, Shenzhen, 518106, China. Welcome to visit our factory

Q2. What kind of production service do you provide

Mold making, die casting, CNC machining, stamping, plastic injection, assembly, and surface treatment

Q3. How about the lead time

Mold: 3-5 weeks

Mass production: 3-4 weeks

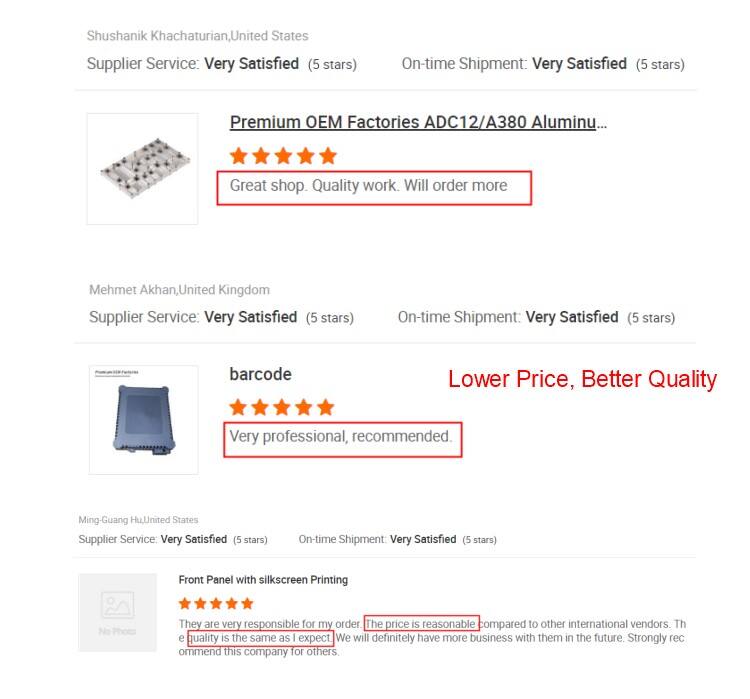

Q4. How about your quality

♦We have got ISO9001:2015 and IATF16949 certificates

♦We will make the operation instruction once the sample is approved

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance

Q5. How long should we take for a quotation

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 2 days

Q6. What is your quotation element

Drawings or Sample, Material, Finish, and Quantity

Q7. What is your payment term

Mold: 50% prepaid, balance after sample approval

Goods: 50% prepaid, balance T/T before shipment.