יציקה מדויקת מפליז היא תהליך של בניית רכיבים תקינים על ידי יריקה מדויקת של מתכת. היציקה המדויקת שלנו מתאימה לתעשייה מגוונת

תהליך היציקה המדויקת של פליז, הנקרא גם יציקה על גבי שבלול, נפתח ביצירת דגם שבלולי של החלק הרצוי. הדגם הזה מוכסֶה בקליפה חרסנית כדי ליצור תבנית. התבנית מחוממת והשבלול נמס או נשרף, כך שנשאר רק הריק, בצורת החלק המבוקש. לאחר שהפליז מתקשה ומקשה, היציקה הגולמית מוסרת מתבנית. לאחר שהפליז התкрепס, הקליפה החרסנית מוסרת והחלק המדויק מוכן. בדקו את רונפנג טעסיי מיציקות סטainless steel כדי ללמוד עוד על הדרך בה אנו יכולים לעזור לכם רבות!

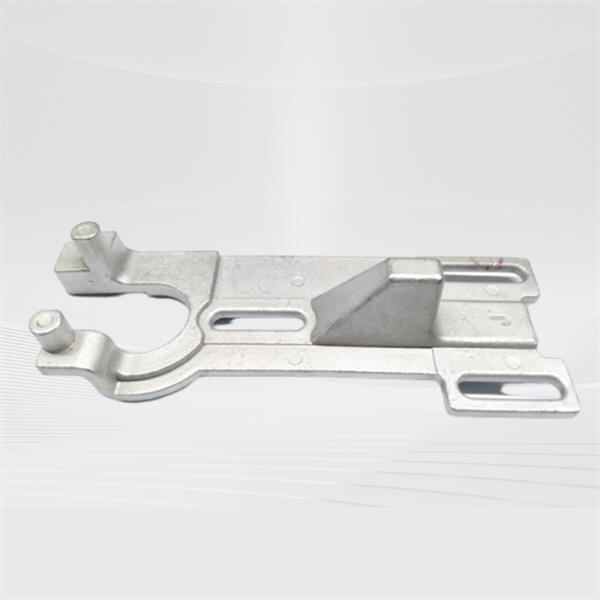

ייצור יציקות פליז מדויקות הוא יצרן וספק של רכיבי יציקה מדויקים הכוללים רכיבי יציקה מדויקים, רכיבי יציקה בשיטה של נייר דבש, ורכיבי מתכת ביציקת חול. התוצאה היא רכיבים באיכות גבוהה שמניבים משטחים חלקים, מה שעושה את ההבדל כאשר יש התחשבות במראה ובשיקולי איכות. תכונות אלו פירושן שיציקות הפליז Runpeng Precision Hardware הן אידיאליות לייצור רכיבים מורכבים מאוד בכמויות גדולות, עבור מגוון רחב של תחומים ויישומים.

להיציקה המדויקת של פליז יתרונות רבים בהשוואה לסוגי יציקה אחרים. אפשר לייצר רכיבים דקים או קטנים או רכיבים בעלי דפנות דקות, תוך שימוש בתהליך הזה, וכך לצמצם את הצורך בעיבוד מכני או סיום. זה מונע את הצורך בעיבוד חם, חוסך כסף ומקצר את זמני הייצור. ה מוצרי ייצור פליז של Runpeng Precision Hardware יכולה לשמש גם ליצירת רכיבים קשיחים ועמידים המתאימים גם ליישומים הקשים ביותר.

ייצור פלדה מדויק הוא תהליך ייצור מדויק ביותר, המאפשר להשיג חלקים עם סיבולת חסימה גבוהה מאוד. תבניות קרמיקה יוצרות פרטים ועומק של מציאות ונaturalות כל כך, עד שהם ייחודיים. הביבלי שלך יהיה עם פרטים ייחודיים ומציאותיים, אך ישנם שחקנים בולטים שייווצרו, כל אחד בארצו. רמת דיוק זו של ייצור פליז מותאם אישית של Runpeng Precision Hardware ממזערת גם את הפעולות המשניות והפסולת, ומביאה לערך טוב יותר וכדאי כלכלי.

עיבוד בקרה משמש ליישום הצורה המדויקת, ומאפשר דמיון נקודתי עם יציקה מדויקת מפליז ועם סובלנות מקרוב 0.002 ועד 0.005, מה שהופך אותו לנפוץ בחלקים עם קיצון של 0.0002 ועד 0.0005. היציקה המדויקת מפליז של Runpeng Precision Hardware משמשת לרכיבים במערכות דלק למנועי מטוסים וכו'. בתעשייה האוטומобильית, היא משמשת לייצור רכיבים למכוניות, לרבות רכיבי מנוע ורכיבי תיבת הילוכים. במכשירים רפואיים, ניתן למצוא יציקה מדויקת מפליז באימפלנטים או בכלים כירורגיים בהם נדרשת דיוק ודיוקיות.