কাস্টম প্রসিশন ব্রাস ব্রোঞ্জ কাস্টিং এলুমিনিয়াম কাস্টিং ফাউন্ড্রি লস্ট ওয়াক্স কাস্টিং সার্ভিস

- বিবরণ

- প্রস্তাবিত পণ্য

রানপেন্গ প্রিসিশন হার্ডওয়্যার

রানপেন্গ প্রিসিশন হার্ডওয়্যার ব্রস, ব্রোঞ্জ, এলুমিনিয়াম এবং আরও অনেক ধরনের উচ্চ গুণবত কাস্টম প্রিসিশন কাস্টিং সার্ভিস প্রদান করে। আমাদের ফাউন্ড্রি লস্ট ওয়াক্স কাস্টিং-এ বিশেষজ্ঞ, যা প্রতি কাস্টেই জটিল এবং নির্ভুল ডিজাইন তৈরি করতে সাহায্য করে।

রানপেন্গ প্রিসিশন হার্ডওয়্যার এর সাথে, আপনি বিশ্বাস করতে পারেন যে আপনার প্রকল্প সর্বোচ্চ দেখভাল এবং বিস্তারিতের সাথে পরিচালিত হবে। আমাদের অভিজ্ঞ ক্রাফটসম্যানদের দল আপনার বিশেষ প্রয়োজনের জন্য সর্বোচ্চ গুণবত কাস্টিং উৎপাদনে নিযুক্ত।

আমাদের কাস্টম প্রিসিশন কাস্টিং সার্ভিস রানপেন্গ প্রিসিশন হার্ডওয়্যার বহুমুখী প্রয়োগের জন্য স্থান দেয়, গাড়ির অংশ থেকে আর্কিটেকচারের উপাদান পর্যন্ত। আপনার প্রজেক্টের আকার বা জটিলতা যা হোক না কেন, আমরা অত্যুৎকৃষ্ট ফলাফল দেওয়ার জন্য বিশেষজ্ঞতা এবং ক্ষমতা সম্পন্ন করতে পারি।

রানপেঙ প্রিসিশন হার্ডওয়্যারে, আমরা ভরসার এবং দক্ষ মোড়ক সেবার গুরুত্ব বুঝতে পারি। তাই আমরা প্রতি বারেই অদ্ভুত ফিনিশ নিশ্চিত করতে শ্রেষ্ঠ উপকরণ এবং সজ্জা ব্যবহার করি। আমাদের ফোকাস প্রিসিশন এবং গুণবত্তা নিয়ন্ত্রণের উপর নির্ভর করে যে আপনার প্রজেক্ট আপনার ঠিক নির্দিষ্ট বিধি অনুযায়ী সম্পন্ন হবে।

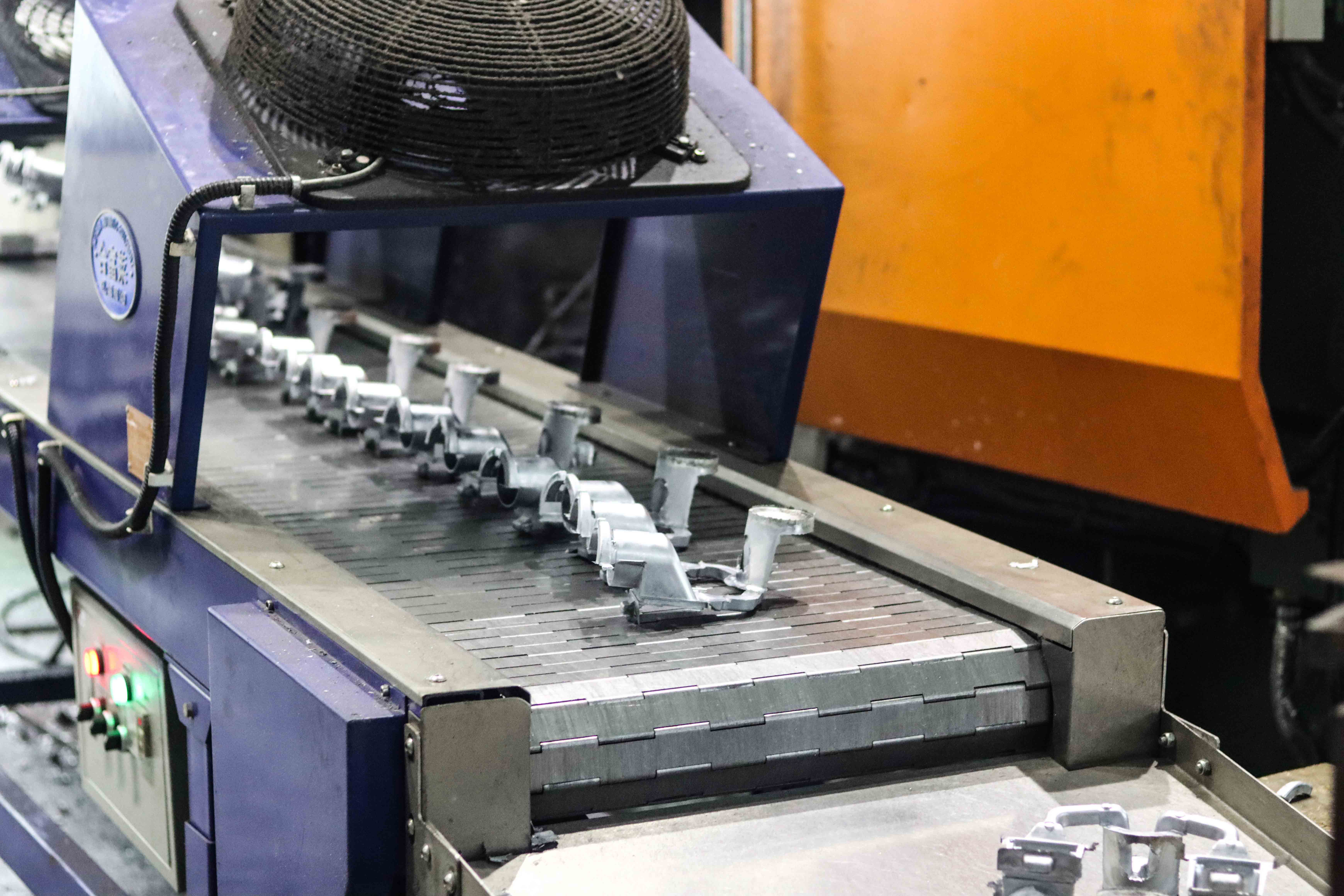

আপনি যদি ক্রাস, ব্রোঞ্জ, এলুমিনিয়াম মোড়ক বা অন্য কোনো উপাদান খুঁজছেন, আমরা আপনার প্রয়োজন মেটাতে বিশেষজ্ঞতা এবং সম্পদ সম্পন্ন করতে পারি। আমাদের ফাউন্ড্রি সর্বশেষ প্রযুক্তি এবং যন্ত্রপাতি দ্বারা সজ্জিত যা সবচেয়ে জটিল প্রজেক্টও সহজে পরিচালনা করতে পারে।

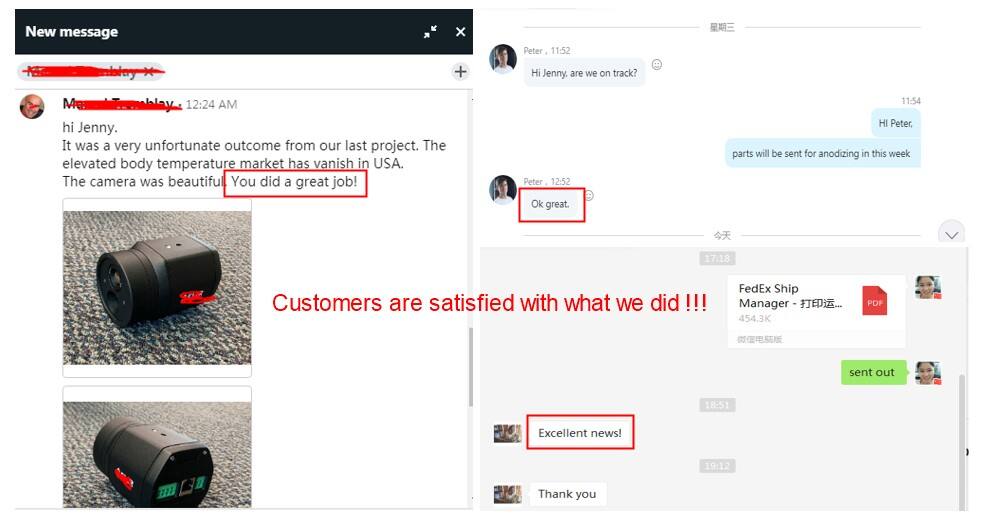

যখন আপনি আপনার কাস্টম প্রসিশন কাস্টিং প্রয়োজনে Runpeng Precision Hardware বাছাই করেন, তখন আপনি অনুপম গ্রাহক সেবা এবং সহায়তা পেতে পারেন। আমাদের দল শুরু থেকে শেষ পর্যন্ত আপনাকে অভিজ্ঞতা দেওয়ার জন্য নিযুক্ত আছে, যাতে আপনার প্রকল্প সময়মত এবং বাজেটের মধ্যে সম্পন্ন হয়।

কাস্টম প্রসিশন কাস্টিং সেবার কথা বললে সেরা থেকে কম কিছুই গ্রহণ করবেন না। Runpeng Precision Hardware-এর ওপর ভরশা রাখুন যেন তারা আপনার আশা ছাড়িয়ে যাওয়া ফলাফল দেন। আজই আমাদের সাথে যোগাযোগ করুন আমাদের সেবার আরও জানতে এবং আমরা কিভাবে আপনার চিন্তা বাস্তবে রূপান্তর করতে সাহায্য করতে পারি তা জানুন।

ছাঁচের উপাদান |

SKD61, H13 |

ক্যাভিটি |

একটি বা একাধিক |

মল্ডের জীবনকাল |

৫০K বার |

পণ্যের উপাদান |

1) এডিসি10, এডিসি12, এ360, এ380, এ413, এ356, এএম20, এএম24 ২) জিন্স এলয়েন্স ৩#, ৫#, ৮# |

পৃষ্ঠ চিকিত্সা |

১) পোলিশ, পাউডার কোটিং, ল্যাকার কোটিং, ই-কোটিং, স্যান্ড ব্লাস্ট, শট ব্লাস্ট, অ্যানোডাইন ২) পলিশ + জিংক প্লেটিং/ক্রোম প্লেটিং/পার্ল ক্রোম প্লেটিং/নিকেল প্লেটিং/কoper প্লেটিং |

আকার |

১) গ্রাহকদের ড্রাইংয়ানুসারে ২) গ্রাহকদের নমুনায় অনুযায়ী |

অঙ্কন বিন্যাস |

step, dwg, igs, pdf |

প্রত্যয়নপত্র |

ISO 9001: 2015 & IATF 16949 |

পেমেন্ট শর্ত |

T/T, L/C, Trade Assurance |

৮০০টি ডাই-কাস্টিং মেশিন |

1 |

৬৩০টি ডাই-কাস্টিং মেশিন |

1 |

৪০০টি ডাই-কাস্টিং মেশিন |

2 |

৩০০টি ডাই-কাস্টিং মেশিন |

1 |

২৮০টি ডাই-কাস্টিং মেশিন |

2 |

১৮০টি ডাই-কাস্টিং মেশিন |

1 |

২. আমরা একটি প্রদান করি প্রতিযোগিতামূলক মূল্য .

৩. উচ্চ নির্ভুলতা, সহনশীলতা ভিতরে থাকতে পারে ±0.01mm .

4. চৌদ্দ বছরের বেশি এক্সপোর্ট অভিজ্ঞতা .

5. ছোট অর্ডার অন্যান্য স্বাগতম।

৬. আমরা প্রদান করি ওয়ান-স্টপ সার্ভিস , মল্ড এবং যোজনা সহ।

৭. আপনার সমস্ত তথ্য আছে গোপনীয় , এবং আমরা NDA স্বাক্ষর করতে পারি

এক-স্টপ সমাধান

মান গ্যারান্টি

গ্রাহক সেবা

আমাদের নিয়মিত গ্রাহক

আমাদের নিয়মিত গ্রাহক

আমাদের নিয়মিত গ্রাহক

আমাদের নিয়মিত গ্রাহক

আমাদের নিয়মিত গ্রাহক

প্রশ্ন ১. আপনি কি একটি কারখানা না ট্রেড কোম্পানি? আমরা চীনের ৬ষ্ঠ ভবন, নং ৫১, নানহুয়ান এভেনিউ, গংমিং, শেনজেন, ৫১৮১০৬ এ অবস্থিত একটি কারখানা।

আমাদের ফ্যাক্টরিতে আসতে স্বাগত।

প্রশ্ন 2. আপনি কী ধরনের উৎপাদন সেবা প্রদান করেন?

মল্ড তৈরি, ডাই কাস্টিং, CNC মেশিনিং, স্ট্যাম্পিং, প্লাস্টিক ইনজেকশন, আসেম্বলি এবং পৃষ্ঠ চিকিৎসা।

প্রশ্ন ৩. ডেলিভারি সময় কত?

মল্ড: ৩-৫ সপ্তাহ

ব্যাটচ উৎপাদন: ৩-৪ সপ্তাহ

প্রশ্ন ৪. আপনাদের মান কেমন?

♦আমরা ISO৯০০১: ২০১৫ এবং IATF১৬৯৪৯ সার্টিফিকেট পেয়েছি।

♦স্যাম্পল অনুমোদিত হওয়ার পর আমরা অপারেশন ইনস্ট্রাকশন তৈরি করব।

♦shipment আগে আমরা 100% পণ্য পরীক্ষা করব।

♦ট্রান্সেকশন অ্যালিবাবা'র ট্রেড অ্যাসুয়ারেন্স মাধ্যমে করা যেতে পারে।

প্রশ্ন ৫. আমাদের একটি অফার জন্য কতদিন লাগবে? বিস্তারিত তথ্য (আপনার ২D/৩D ড্রাইং বা নমুনা) পাওয়ার পর, আমরা ২ দিনের মধ্যে আপনাকে অফার দিব।

Q6. আপনার উদ্ধৃতির উপাদান কি?

ড্রাইং বা নমুনা, উপাদান, শেষ হওয়া, এবং পরিমাণ।

প্রশ্ন ৭. আপনার ভালো পরিশোধ শর্ত কি?

মোড: ৫০% আগে পেমেন্ট, নমুনা অনুমোদনের পর ব্যালেন্স। পণ্য: ৫০% আগে পেমেন্ট, পাঠানোর আগে T/T ব্যালেন্স।