CNC machining has been a preferred method for small to medium production of parts. Is CNC machining cost-effective for mass production of high-quality parts? Traditional Machining takes Onslaught to Small Batch 3D Printing Lets break down the benefits of conventional machining compared to 3D printing when producing small-med batch production run parts.

Is CNC machining an affordable way to make quality parts in volume

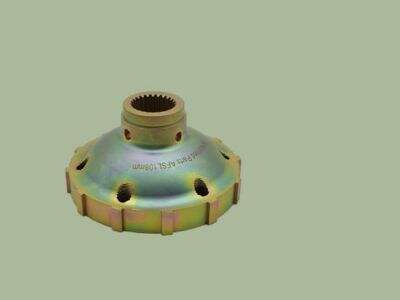

For manufacturing high-quantity, quality assurance parts are machined via precise laser cnc machining & stamping at an affordable rate. CNC routers form parts of intricate detail with no variation in quality. The cost per item is also higher in the CNC machining compared to 3D printing, but it reduces with size. This means that for low- to mid-volume production of parts, CNC machining can realize some pretty substantial cost savings in the long term. Also, CNC machining supports a variety of materials to be worked with in terms of production solutions.

What are the benefits of conventional machining versus 3D printing for small/medium batch parts

Conventional machining such as CNC machining offers many advantages compared to 3D printing when it comes to small- and medium-sized batch production of parts. One of the main benefits is the precision and accuracy of parts that it can create. The scale of CNC machines allows for precise features and fine details that can be harder to realize through 3D printing. It is also a fact that traditional machining processes like cnc metal stamping may be able to produce parts much faster than 3D printing, which means you can rely on them when time and volume are critical. Moreover, traditional machining techniques have been around for a long time and are used throughout the manufacturing industry, so they may be considered to be more reliable than newer technologies such as 3D printing. As a general rule for small to medium sized run parts production, traditional manufacturing methods such as CNC machining is the most cheap and effective way of manufacturing high quality metal products.

SideWhere can wholesale purchasers find a trusty CNC machining service with competitive pricing

Runpeng Precision Hardware provides several cnc machining for wholesale purchasers that enables to make small to mid-sized batch of parts. We are a reliable business partner and want this quality philosophy product in a more accessible to manufacturers who have less budget. Our modern machine shop and skilled work force enables us to produce high quality parts quickly as needed for our customers. Whether you are looking for prototypes or production runs, Runpeng Precision Hardware is committed to providing quality machined parts at a fair price.

In comparison to traditional production methods, for mass production, efficiency of CNC machining is how

For mass manufacturing of parts, there are several benefits to using CNC machining as opposed to traditional techniques. CNC machine works non-stop and does not require the human touch, which means these offer faster process time as well as better efficiency. And because CNC machining a part has fewer restrictions on physical and geometric features, it offers greater flexibility of design even when the part in question may have intricate contours or tighter tolerances. CNC machining provides more precision and uniformity than traditional machining options, which minimizes the chances of error and rework. Since it is more efficient, carrying increased efficiency into account benefits the company that chooses CNC when producing countless parts.

What should you consider when trying to decide between CNC machining and 3D printing small-to-medium-size batch parts

When comparing 3D printing vs CNC machining for low-volume production parts, there are many factors to consider. CNC machining may not be able to produce complex, intricate designs in this manner as 3D printing can. But for larger production runs, 3D printing can be slower and more expensive than CNC machining. In contrast, CNC machining can give quite faster production time and good efficiency especially for small to medium batch parts means a cost-effective approach if you are not looking to spend much over manufacturing. In addition, we can achieve more variety of materials to be processed on CN C machining services.

Table of Contents

- Is CNC machining an affordable way to make quality parts in volume

- What are the benefits of conventional machining versus 3D printing for small/medium batch parts

- SideWhere can wholesale purchasers find a trusty CNC machining service with competitive pricing

- In comparison to traditional production methods, for mass production, efficiency of CNC machining is how

- What should you consider when trying to decide between CNC machining and 3D printing small-to-medium-size batch parts