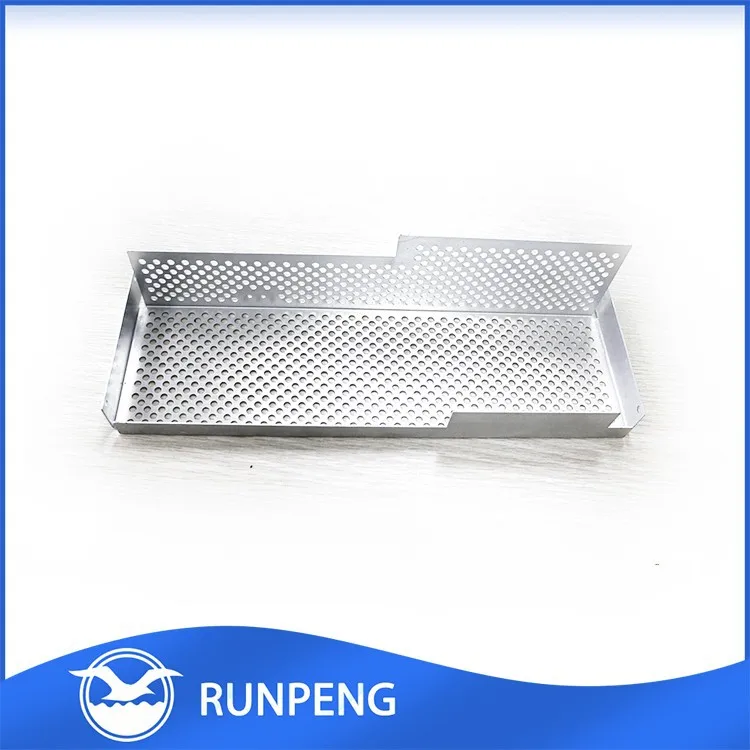

บริษัท รุ่นเผิง เพรสซิชั่น ฮาร์ดแวร์ ใช้เทคโนโลยีการขึ้นรูปโลหะความแม่นยำสูง การตรา ในการผลิตชิ้นส่วนจากโลหะ ซึ่งต้องมีความแม่นยำอย่างมากเพื่อให้มั่นใจว่าชิ้นส่วนจะพอดีกับตำแหน่งที่กำหนดอย่างสมบูรณ์ เพื่อให้บรรลุเป้าหมายนี้ รุ่นเผิงจึงอาศัยสิ่งที่เรียกว่าการควบคุมค่าความคลาดเคลื่อนและการรับรองคุณภาพ ซึ่งเป็นเหมือนกฎเกณฑ์และขั้นตอนตรวจสอบเพื่อให้มั่นใจว่าทุกชิ้นส่วนโลหะนั้นมีความเหมาะสมแม่นยำตามที่ต้องการ

ความสำคัญของความแม่นยำในการขึ้นรูปโลหะ

คุณต้องการให้ชิ้นส่วนโลหะของคุณพอดีกันอย่างแนบสนิทหรือไม่? ลองจินตนาการว่าคุณกำลังต่อจิ๊กซอว์ แต่ชิ้นส่วนทั้งหมดมีขนาดต่างกัน มันจะกลายเป็นงานที่ไร้ประโยชน์! นั่นคือเหตุผลที่เราที่รันเผิง เพรซิชั่น ฮาร์ดแวร์ ได้รับรองว่าชิ้นส่วนทุกชิ้นของเราเป็น การปั๊มโลหะด้วยความแม่นยำแบบกำหนดเอง เพื่อความแม่นยำสูงสุด

เคล็ดลับในการรักษาระยะความคลาดเคลื่อนที่แคบสำหรับชิ้นงานปั๊มโลหะ

เพื่อให้มั่นใจว่าทุกอย่างถูกต้องแม่นยำ บริษัท รันเผิง เพรซิชั่น ฮาร์ดแวร์ ได้ออกแบบเครื่องพิเศษโดยใช้การเชื่อม ซึ่งมีความสามารถสูงในการตรวจสอบให้แน่ใจว่าชิ้นส่วนแต่ละชิ้นสมบูรณ์แบบ เรายังทำการทดสอบเครื่องอย่างสม่ำเสมอเพื่อตรวจสอบว่าเครื่องทำงานได้อย่างเหมาะสม และพนักงานของเราได้รับการฝึกฝนให้มีความรอบคอบและใส่ใจในรายละเอียดขณะผลิตชิ้นส่วน

รับประกันคุณภาพด้วยการตรวจสอบคุณภาพอย่างเข้มงวด

การรับประกันคุณภาพเป็นเหมือนฮีโร่ที่คอยยืนยันว่าทุกสิ่งที่เราผลิตนั้นมีคุณภาพสูงสุด ที่ Runpeng Precision Hardware เราตรวจสอบทุกชิ้นส่วนที่เราผลิต หากมีสิ่งใดผิดพลาด เราจะวิเคราะห์หาสาเหตุและแก้ไขให้ถูกต้อง ด้วยวิธีนี้ ชิ้นส่วนที่ดีที่สุดเท่านั้นที่จะถูกส่งออกไปยังโลกภายนอก และสามารถนำไปใช้ในโครงการขนาดใหญ่ต่างๆ ได้

การบรรลุความสม่ำเสมอและความแม่นยำในการขึ้นรูปโลหะด้วยเทคโนโลยีขั้นสูง

เทคโนโลยีมีประโยชน์มากสำหรับเราที่รันเผิง พรีซิชั่น ฮาร์ดแวร์ เรามีคอมพิวเตอร์และหุ่นยนต์ที่สามารถเคลื่อนไหวได้อย่างแม่นยำสูง แม่นยำกว่าการเคลื่อนไหวด้วยมือของมนุษย์หลายระดับอย่างมาก คือเทคโนโลยีของเราที่ทำให้มั่นใจได้ว่าทุกชิ้นส่วนจะมีคุณภาพดีเท่ากันทุกชิ้น

ความสำคัญของการควบคุมค่าความคลาดเคลื่อนสำหรับชิ้นงานขึ้นรูปโลหะ เพื่อให้เป็นไปตามข้อกำหนดอุตสาหกรรมอย่างเข้มงวด

ใน การผลิตด้วยการปั๊มโลหะ , เราจำเป็นต้องปฏิบัติตามมาตรฐานอุตสาหกรรมเพื่อดำเนินงานให้สำเร็จ และการควบคุมความคลาดเคลื่อนคือสิ่งที่ทำให้เราสามารถทำเช่นนั้นได้ ซึ่งหมายความว่าชิ้นส่วนของเราจะไม่ใหญ่หรือเล็กเกินไป แต่มีขนาดที่เหมาะสมพอดี "นี่เป็นสิ่งสำคัญอย่างยิ่งสำหรับผลิตภัณฑ์อย่างรถยนต์หรือเครื่องบิน ที่ทุกชิ้นส่วนต้องสมบูรณ์แบบ เพื่อให้ทุกอย่างทำงานได้อย่างปลอดภัยและถูกต้อง" ที่รันเผิง เพรซิชั่น ฮาร์ดแวร์ เราถือว่าหน้าที่ของเราคือการเข้าใจและปฏิบัติตามมาตรฐานทางกฎหมายเหล่านี้

สารบัญ

- ความสำคัญของความแม่นยำในการขึ้นรูปโลหะ

- เคล็ดลับในการรักษาระยะความคลาดเคลื่อนที่แคบสำหรับชิ้นงานปั๊มโลหะ

- รับประกันคุณภาพด้วยการตรวจสอบคุณภาพอย่างเข้มงวด

- การบรรลุความสม่ำเสมอและความแม่นยำในการขึ้นรูปโลหะด้วยเทคโนโลยีขั้นสูง

- ความสำคัญของการควบคุมค่าความคลาดเคลื่อนสำหรับชิ้นงานขึ้นรูปโลหะ เพื่อให้เป็นไปตามข้อกำหนดอุตสาหกรรมอย่างเข้มงวด