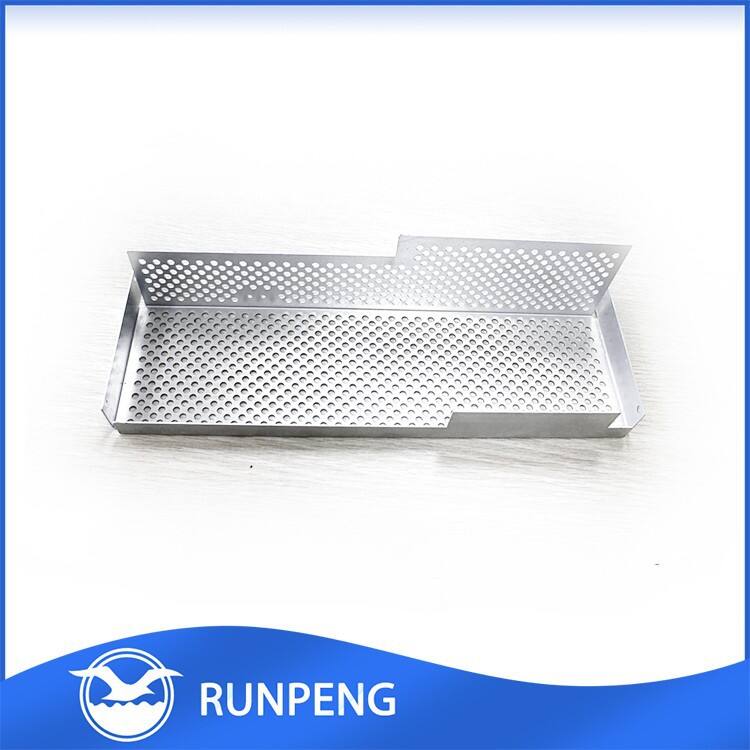

Is é stampáil ard-athraithe mata is éard atá i gceist le próiseas agus modh oibre mata a úsáidtear chun mata a fhoirmiú agus a bhaint ar bealach tapa agus costais éifeachtach. Tá an bpróiseas seo riachtanach chun go leor de na hábhar a úsáidimid gach lá a tháirgeáil, lena n-áirítear comhpháirteanna carr agus innealtóga baile. Tá Runpeng Precision Hardware i réamhréiteoir sa fhaisin seo den teicneolaíocht, agus agus ag fuarthainn bhealaí nua chun stampáil mhata a dhéanamh níos fearr agus níos tapa i gcónaí. Ach cad iad roinnt de na hathruithe is fearr a bhfuil ag déanamh ar stampáil ard-athraithe mata níos ionramaí

Feidhmíocht stampála mata, anois is féidir leat táirgeáil a dhéanamh níos tapa

Ag Runpeng Precision Hardware, rinneamar ár stampáil mhionsonraithe miotail próiseas an-tapa. Tá maonlaithe againn a bhfuil níos mó tuiscint acu agus a dhéanann codanna airgid as gasta, gan earráid. Mar sin is féidir linn níos mó codanna a tháirgeadh i níos lú ama, rud a bhaineann tairbhe d'ár gcuideachta féin, ach freisin do ár gcustaiméirí. Trí an bpróiseas a shimpliú, cabhraímid le costais a choinneáil thíos agus cuireann sé sástacht ar gach duine

Conas a chabhraíonn teicneolaíocht fearr le bacaireacht a dhéanamh níos cruinne

Tá bacaireacht airgid tar éis a bheith an-scrúdaithe le teicneolaíocht. Inniu, is féidir le maonlaithe tomhas agus gearradh airgid le cruinneas iontach. Ciallaíonn sé seo go bhfuil níos lú ábhair chaillte agus níos fearr glacadh ag gach mhaisín. Tá an scrúdaitheacht seo thar a bheith tábhachtach, mar is é sin a cheadaíonn do na codanna dul isteach go foirmcheart i dtáirgí cosúil le gluaisteáin agus fónanna

Ag taipéalú ar ghilíseanna nua a ligfidh níos tapaí agus saol faide a úsáidtear i mbacaireacht

Oibríonn Runpeng Precision Hardware freisin ar chineálacha nua de mhaitéarail, ar a dtugtar comhdhúil, a is féidir stampáil go tapa agus atá an-mhaith le haghaidh tréimhse fada. Tá na comhdhúile nua níos láidre agus níos mó ina gcomhdhúile dúchasa, rud a chiallaíonn go bhféadfaimid táirgí níos slándálaí agus níos oiriúnaí a thógáil. Ach cosúil le comhdhúile is fearr a aimsiú, ach amháin, leis na hairgeadra is fearr, déanaimid rudaí níos fearr, níos níos airde

Réitigh Fhabraice Smart, Éifeachtaíocht go dtí an MAX

Bogearraí fuar a ligeann dúinn gach rud a rialú i ár bhfabraicí. Leis an mbogearraí seo, is féidir linn gach próiseas a dhearbhú agus a leanúint suas i stampáil . Inseann sé dúinn cé mhéad maitearail at dhíth orainn, cé mhéad páirt is féidir linn a dhéanamh sa chloig, agus conas ár gcuid uirlisí a choimeád ag rith go smooth. Cuireann sé seo cosc ar dhrámaí a dhéanamh agus mearbhall a chúisithe, ag cinntiú go ndéanaimid seachadadh ar tháirgí móra i gceart ama

Cad am é seo don stampáil ard-luasach airgid

As perspéictíocht shásaíoch, táimid, sna Runpeng Precision Hardware, ag tnúth faoi theicneolaíochtaí nua cosúil le roboit agus AI. D’fhéadfadh na huirlisí sin simpliú brúchán Meallta go dtí níos faide agus an ráta a mhéadú. Smaoinigh ar róbóit a sheachaidh tascanna chomh tapa agus is gá don líne fábráide, nó intleacht shaintiúil a dhéanfaidh an difríocht idir inneall a dhearbhú sula mharfann sé. D’fhéadfadh sé seo athrú iomlán a dhéanamh ar an mbealach a dhéanaimid rudaí agus ár bhfórsaí táirgeacháin a bheith níos éifeachtaí

Clár na nÁbhar

- Feidhmíocht stampála mata, anois is féidir leat táirgeáil a dhéanamh níos tapa

- Conas a chabhraíonn teicneolaíocht fearr le bacaireacht a dhéanamh níos cruinne

- Ag taipéalú ar ghilíseanna nua a ligfidh níos tapaí agus saol faide a úsáidtear i mbacaireacht

- Réitigh Fhabraice Smart, Éifeachtaíocht go dtí an MAX

- Cad am é seo don stampáil ard-luasach airgid